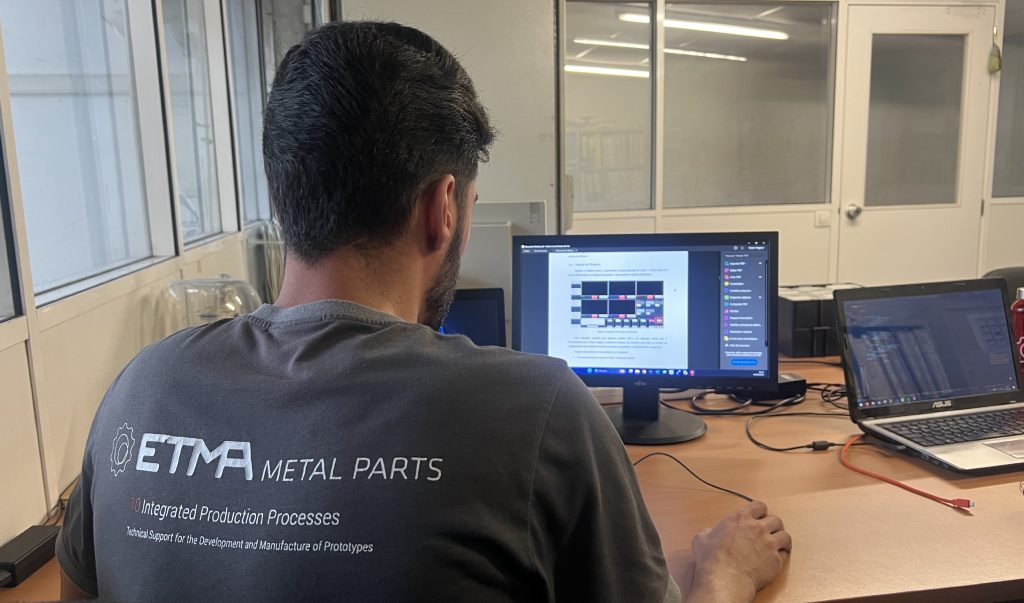

The R&D Department of ETMA developed a monitoring system that provides support information to the operators regarding the production processes of the company, namely regarding the process of cold forging in horizontal and vertical presses.

Although the market has similar systems, ETMA felt the need to develop its own system, more flexible and customised to its own needs, , therefore reducing fewer non-OK parts and damaged tools.

In this process, the wire forming is induced in relation to a pre-imposed shape and, this way, the production of several screw formats is performed. In order to measure the strength and consistence of these blows, several piezoelectric sensors are installed.

Through this system, the operators have the possibility to monitor the strength of the blows, number of strokes, quantity of produced parts and consistency of product production.

The development of this monitoring system will, thus, allow the availability of information on several production quality standards, not only regarding the products produced, but also of the normal machine parameters, with the former system already integrated in the machine being replaced, given that it presented several problems and functions that were not appropriate to the production.

This is another example of the improvement of ETMA’s production processes, through its internal technical know-how and, consequently, of quality assurance of the products produced. In this particular new system, the next step will be its extension to all production processes within the company.