ETMA has recently made another new investment in its range of manufacturing equipment by purchasing a YESWIN YBP-13B6S.

With the acquisition of this higher capacity horizontal press with multiple stations, ETMA will now be able to use 15mm wire and 6 stations, which allows from now on to forge larger and more complex parts. Keep in mind that, up until now, its capacity was limited to the use of 12mm wire and 5 stations.

Through the process of Cold Forging/Screws, which is included in the 10 Integrated Productive Processes system, for the manufacturing of metal parts, screws and rivets, ETMA now has the capacity to work with 1.5mm to 15mm diameters wire and different materials in two-stroke and multi-post horizontal presses. It can also finish the forged parts in secondary operations by turning, transfer turning and milling in centers with pallet changer.

ETMA’s production capacity, ensured by its vast experience of 8 decades in Cold forging/Screws processes, has a diverse range of equipment, of which stand out:

- 2-stroke stamping machines:

- Carlo Salvi RF/SV; RF/SV 550; RF/DL 330 SV, 560/SV

- Chun Zu CDH82

- Pressvit SU-8

- 4-stroke stamping machines:

- Multipress MP410

- 5-stroke stamping machines:

- Moroni MB765/5

- Multipress 510

- 6-stroke stamping machines:

- Lian Shyang NF-11B-6S

- Slotting machines:

- Mauro Pasqualli

- Cappeli

- Bolt head trimming machines:

- Pressvit E14

- Thread rolling machines:

- Ingramatic RP-1, GR-1, RP-3

- Pressvit B 88, B 120

In addition to the variety of possible raw materials, such as aluminum, stainless steel, brass, copper, and steel, from the diversity of parts that ETMA manufactures, the following stand out:

- Screws with different threads: plastic screws (EJOT PT type); hardened self-tapping sheet metal screws (Parker-Kalon); wood and particle board screws (AGL); metric screws (from M2 to M12) property classes up to 12.9; and trilobular self-tapping screws (DIN 7500 standard);

- Rivets: semi-tubular, blind, centerers, and shafts;

- Compression limiters, bushing, spacers, eyelets, and more.

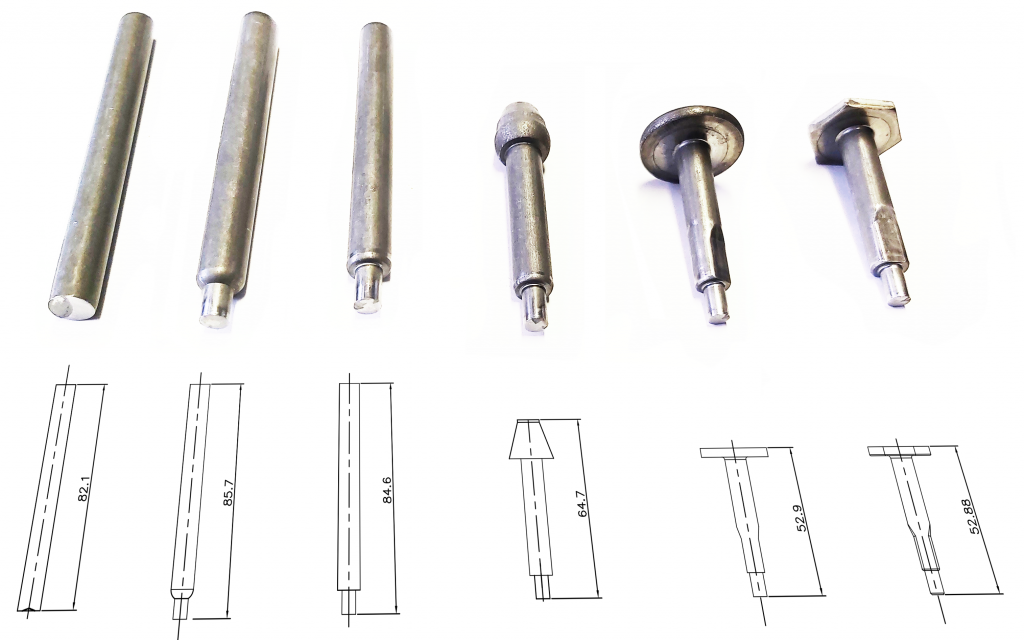

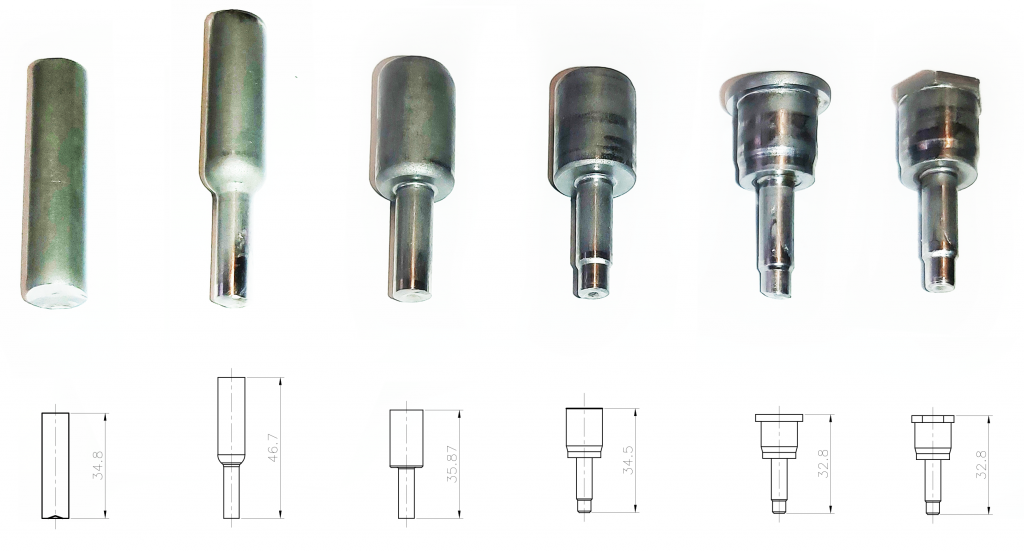

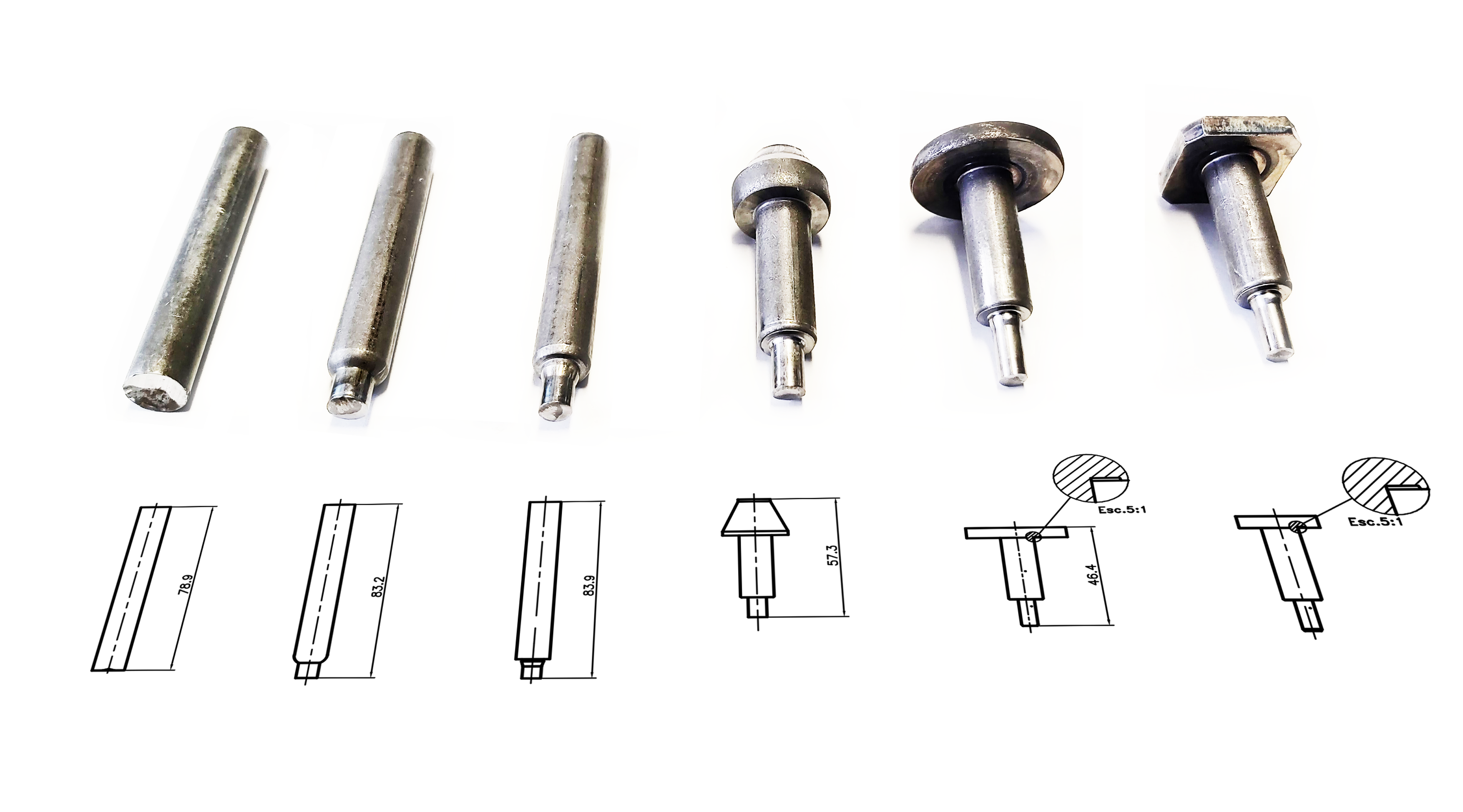

Some examples of parts that can be produced on YESWIN YBP-13B6S:

Watch the manufacturer’s video about this equipment: