In response to the demands of a constantly changing world and technological updates, knowledge is an immeasurable wealth in every company, even more so when it comes to the industry sector.

Consequently, investing in the creation of knowledge is a way to stimulate innovation, as well as to highlight business competitiveness and performance in the long-term. Research & Development (R&D) is, therefore, one of the main drivers of innovation and a way to expand performance within companies.

ETMA is not indifferent to this fact, meaning that its investment in innovation and continuous development of knowledge has been a major concern for the company. The creation of its own R&D Department was a natural step in the company’s growth and evolution, enabling the creation of conditions to extend its competences, namely in terms of its production processes, always focused on a market with great expectations regarding efficiency and quality.

Part of a demanding sector, such as metallurgy and metalworking, ETMA’s evolution is intrinsically connected to the steady evolution of technological progress, investing in innovative (and distinctive) methodologies and equipment, and thoroughly working to improve its efficiency and quality standards. Innovation, knowledge and technology are, therefore, its priorities. After all, Innovation is one of its values.

EIGHT-DECADE TECHNICAL KNOW-HOW

With more than 80 years of technical know-how, which enables ETMA to respond accountably and efficiently to the demands of the markets in which it operates, its goal is to always be one step ahead, focused on the internal needs of the company and continuous improvement of its production processes, in order to better serve its clients.

This way, when it comes to deepening knowledge and promoting continuous learning and improvement, ETMA joins those who help to optimise the production resources and contribute to an increasingly avant-garde and sustainable technological development, alongside its expertise.

However, the market is not always prepared. And when no solution is found in the market, ETMA has the ability to develop its own machines, equipment and software, producing solutions in-house, and therefore offering something totally different from what the market has to offer.

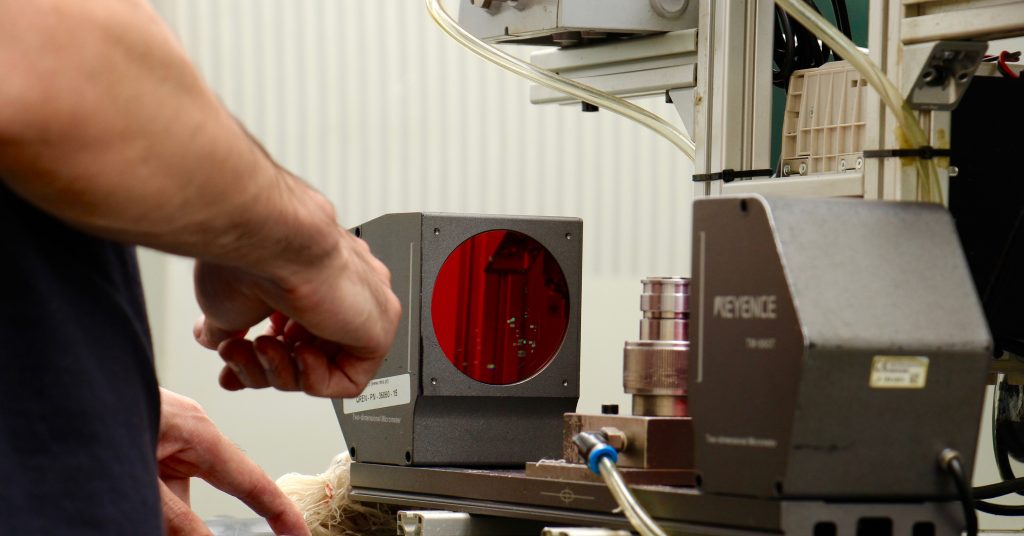

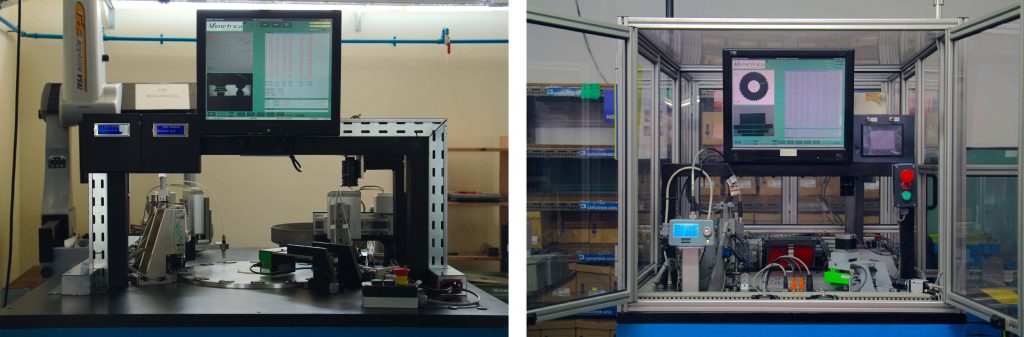

The R&D Department, which was created based on the natural evolution of the Maintenance and Automation Department, is fully targeted to the company’s innovation projects and has had a significantly high investment, not only through machine acquisition, but also through the investment in the internal development competences of its own equipment.

Innovation is increasingly present in ETMA’s day-to-day, always seeking the best. Innovating is providing the company the ability to not depend on others and to innovate alone. Therefore, the R&D Department is responsible for coming up with answers to the daily challenges ETMA faces, finding and developing solutions.

TAILORED SOLUTIONS FOR EACH CLIENT’S NEEDS

As emphasised by Ricardo Pereira, Production Manager, regarding the R&D Department, “since at ETMA we have a very customised product, tailored to the needs of each client, we do not have a pattern. Every case is unique and the company has the flexibility to deal with each one. And innovation is a crucial factor here”.

Currently, “the department is comprised of employees exclusively dedicated to the study and development of systems that do not exist in the market or, if they exist, they are not focused on ETMA’s needs. It also counts on the support of the Maintenance and Automation Department”.

Within this context, “first the R&D Department performs the study, presents the idea, develops the prototype and, later, puts it into practice and applies it to the new solutions it has developed. All this happens in close connection with the Maintenance Department, which, in addition to the support provided, also facilitates the applicability of the solutions presented”, adds Ricardo Pereira.

Within this evolution timeline, ETMA’s R&D Department has already developed three coordinate-measuring machines and some prototypes. Another excellent work example performed by this department is the Effort Monitoring System, which, “in addition to being used in the cold forging process, will be applied in machines for other production processes in the future”.

Ricardo Pereira also states that “several projects are being developed, among which high-speed sorting machines; robotic packaging systems near the production machine; resistance welding monitoring system; automation of raw material warehouses and replacement components for tools that support the production sectors; and a real-time data acquisition system of the wireless production equipment”. The dimensional inspection systems to support production, currently in the validation process by ETMA’s Quality Department, are already in the finalisation phase”.

Therefore, ETMA’s R&D Department is a winning strategy whose implementation helps improve processes and develop new techniques or technologies inside the company.