Quality control in the industry is an increasingly essential factor to define and standardize production in the entire workflow, making it possible to detect day-to-day failures and thus improving and standardizing processes.

Being aware that its success will also depend on its ability to produce products whose quality meets or exceeds the expectations of its customers, ETMA continuously works to improve its standards of efficiency and quality.

Therefore, ETMA’s evolution is intrinsically linked to the constant commitment to technological progress, in which it bets on innovative methodologies and equipment. In addition, it has been counting on the contribution and performance of its own R&D Department for some time.

THE R&D DEPARTMENT’S ROLE IN SUPPORTING QUALITY CONTROL

By prioritizing strategic factors, such as innovation, knowledge, and technology, ETMA seeks, on a daily basis, to ensure production quality, investing in new measurement systems that are suitable for product inspection and that adopt an inspection frequency compatible with production.

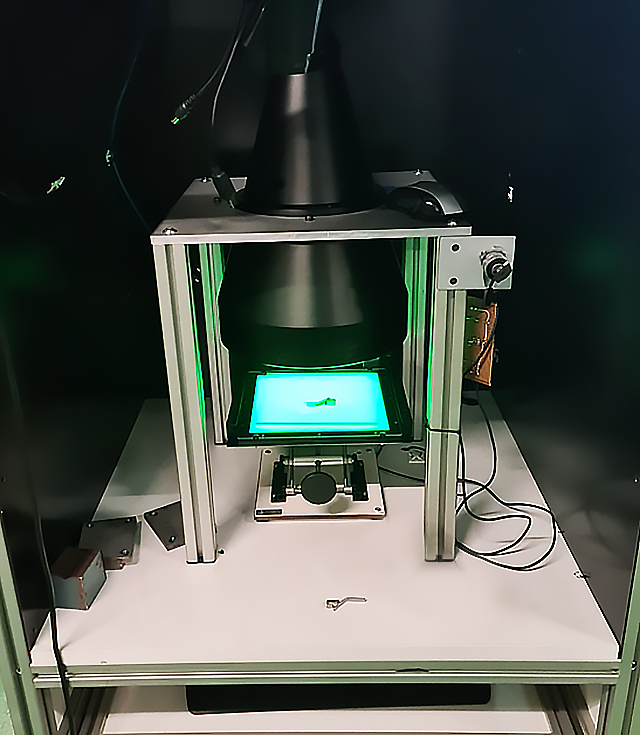

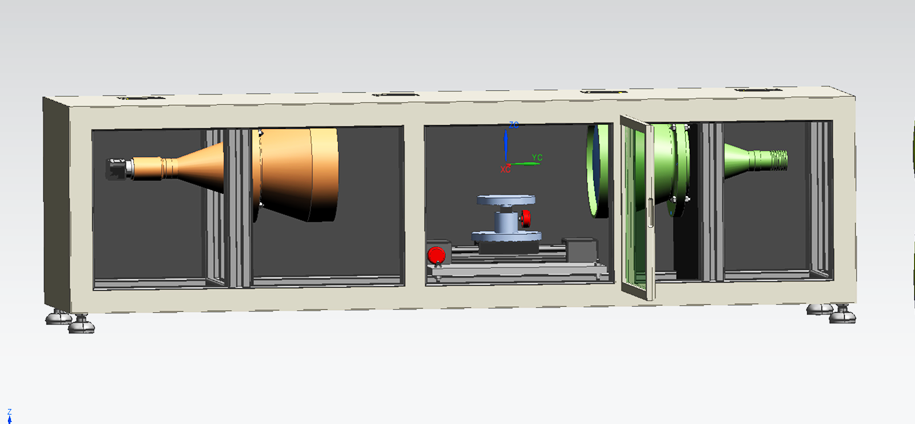

From its R&D Department and taking advantage of its in-house know-how to develop its own quality control tools, ETMA has been developing optical measuring machines that enable a quick and dedicated control of the production of each part.

One of these equipment developed by ETMA, designed to measure flat parts with a visual field of 200 x 200 mm, has been operating for a few months in the Bihler sector.

More recently, the R&D Department delivered to the Lathe Turning and Screwing sector two new machines with a visual field of 70 x 70 mm and 120 x 120 mm.

All equipment developed by ETMA’s R&D Department is subsequently submitted to all necessary validations and calibrations by the Quality Department.