In this article, we will detail the system of the 10 integrated production processes, highlighting their usefulness and advantages for customers.

Introduction

ETMA works according to a simple and very effective methodology, created to keep in mind the needs of its customers and take into account current requirements in the industrial subcontracting market: flexibility, ability to provide knowledge that can optimise project development and, therefore, last but not least, the technological component, means of production and their intrinsic link to the concepts disseminated by industry 4.0.

From project to product

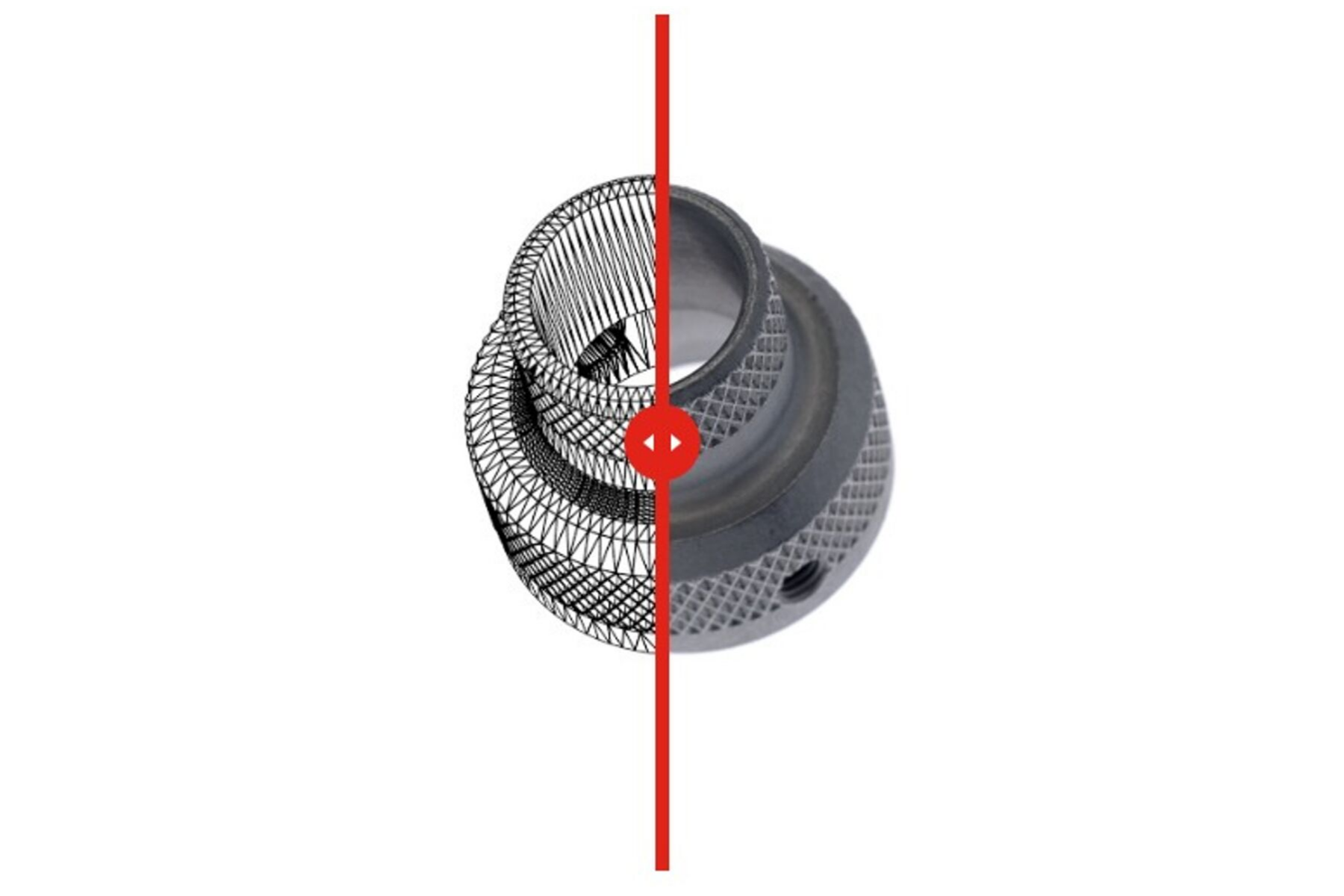

The system of 10 integrated processes begins in development and prototyping and ends in serial production, going through several different manufacturing processes that can be complementary to each other, and ending in quality management, where production is certified and specifications guaranteed to produce excellent parts.

These 10 processes are fully carried out at ETMA Metal Parts facilities, thus enabling the customers, whenever they wish, to follow in real time different phases of their project execution, either visiting our physical facility or remotely – via a conference call, for example.

If you would like to know each of the 10 processes in detail, simply click one of the following items:

- Prototypes

- Tools and equipment

- Turning

- Stamping and automatic formation

- Cold forging/screws

- Wire forming

- Thermal treatments

- Surface treatments

- Assembly/Welding

- Inspection/Selection

The advantages of methodology

ETMA is a family-run company with nearly 80 years of history – now in its 3rd generation, which has always struggled to provide the most efficient response to the challenges posed by its customers. It is this history of the company and its accumulated experience that support the creation of the system of 10 integrated processes, a qualified response to the customers‘ requirements and for the benefit of their projects, which translated into lasting and trusting business relationships.

Today, ETMA can proudly say that 85% of its customers have maintained this business relationship for over 15 years and the perspective is that it will continue in the future.

For ETMA’s customers, the advantages are clear and can be summarised in three major value-added pivots:

- Flexibility: Since the choice of production process that best responds to the customer’s project is not always clear, there may be optimisation of costs or production times, or even product quality when the distribution of production processes to be carried out in a given project. At ETMA, it is possible to make this selection internally, offering a very interesting flexibility in the customer’s eyes. This flexibility is highly evident in the Forging case study.

- Greater process control: The possibility of all 10 processes being operated in the same production facilities allows efficient process control. This eliminates the negative externalities arising from the physical distance that sometimes separate the different stages of production, whether related to transport, the multiplicity of suppliers or even cultural issues, which require a more permanent availability by the customer.

- Cost optimisation: The tangible advantage of the 10 production processes is the significant cost savings. The possibility of the customer being able to use an integrated system guaranteed by the same supplier, in one single geographical point, can be decisive for good project profitability.

The team

Throughout this process, the customer is supported by a team of three managers.

- The Project Manager: Monitoring of the production process and pipelining the customer’s project(s) is ensured by ETMA’s Project Manager – the professional who has the direct responsibility to follow-up the work and will always be available to meet your needs. The role of the Project Manager is particularly relevant to ensure the project follow-up after adjudication until it goes into serial production. The role of the Project Manager is particularly relevant to ensure the project follow-up after adjudication until it goes into serial production.

- The Sales Manager: ETMA Metal Parts‘ sales team is able to unlock any language barrier – it provides qualified managers prepared to deal with the Portuguese, Spanish, French, English, German and Czech markets. They are technically equipped to ensure the correct exchange of information between the customer and the company during the negotiation and part development stages.

- The Back Office Manager: They support the logistics section and the whole order/delivery process, ensuring the bridge between ETMA and the customer.

Quality

To guarantee the quality of the parts produced, ETMA also has a well-prepared team and equipment that ensures process control and also tools that ensure the good performance of the entire quality management process.

The entire organisation is certified by ISO 9001:2015, IATF 16949:2016 quality management standards and the ISO 14001:2015 environmental standard.

This link has access to the certificates mentioned.

Conclusion

In an extraordinarily competitive market, where the best prices are increasingly being demanded for increasing quality, ETMA responds with a methodology and administrative structure that has allowed it to maintain strategic business relationships based on trust and credibility, creating a lasting business relationship.

Naturally, this ability to have in-house a series of production processes that are often complementary to each other, gives customers an important degree of flexibility. In this way, it is possible to circumvent unforeseen or immediate development needs by keeping the project in the same place of production and benefit from all the added value, whether in terms of costs or process control.

To learn more about the 10 integrated processes look at Audi’s case study or download our catalogue.