This month we will detail the Cold Forging production process, letting you know its usefulness, its advantages and the steps that constitute our internal procedure whenever we receive a new project.

What is Cold Forging?

Cold forging is a forming production process, where there is no material removal or addition. This process consists in the application of extremely high pressures to the material, causing its deformation (forming) to a pre-imposed form. The name “cold” is due to the fact that the process takes place with the material at room temperature, without pre-heating. Consequently, the mechanical resistance level of the material is higher than in a “heat” process.

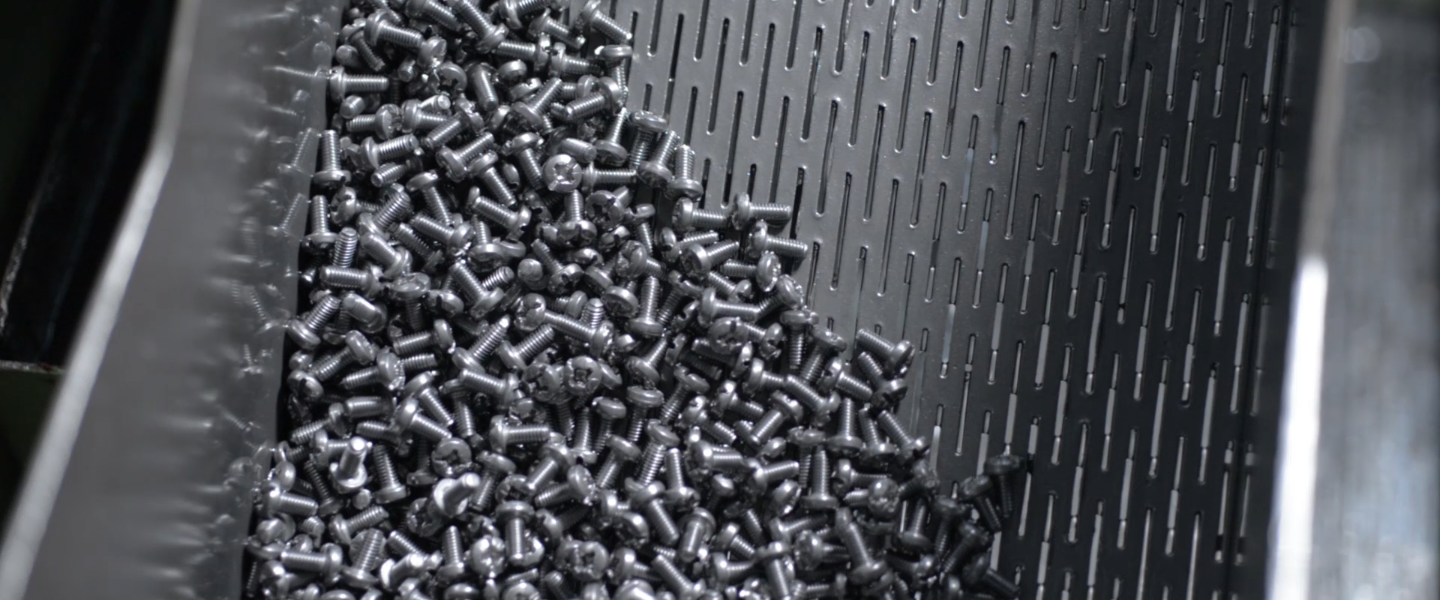

The capacity for plastic deformation of metal (conformability or ductility) is therefore lower, so the achievement of more complex geometry is limited. Usually this process is used to produce parts with relatively reduced sizes and weight, such as screws, hooks, rings, rods, shafts, among others.

Advantages of the cold forging process

The main advantages of the process include the high dimensional quality, excellent surface finishing, raw material savings and greater productivity, avoiding side effects of hot work, such as oxidation, decarburisation and thermal contraction. This process is, for all these reasons, highly competitive.

A great example is described in this case study, where the application of a cold forging process as an alternative to turning, allowed savings of about 35% to one of our clients.

The right procedure for a good execution

For a good execution of the forging process, ETMA follows a procedure that consist in the following steps:

- Analysing the client’s final drawing to check sizes, dimensional tolerances, among others;

- Confirming the reductions of the area to be achieved, considering the limits allowed by the material in use;

- Calculating the part volume and weight from the forged drawing;

- Determining the initial length of the preform from the weight calculated and using, whenever possible, standard patterns;

- Delineating an operation plan where the processing steps are included, from the cut to the final forging operation, the process limits, such as maximum length of the preform out of the higher and lower matrix, necessary forming steps and also equipment limitations, such as extraction course, capacity of material displacement and forming speed;

- When projecting the tools, tailor them to the company’s “patterns” and, at that moment, confirm that the extraction course allows the part to be truly loose of matrix and in conditions to allow the transfer system between slides;

Final thoughts

The cold forging process is, therefore, a very useful process in all our 10 production processes and, although it may have some application limitations, it really contributes for cost savings and resource optimisation.

To find out more about this process, discover an actual application case of this process in one of our clients or download our catalogue.

[…] Flexibility: Since the choice of production process that best responds to the customer’s project is not always clear, there may be optimisation of costs or production times, or even product quality when the distribution of production processes to be carried out in a given project. At ETMA, it is possible to make this selection internally, offering a very interesting flexibility in the customer’s eyes. This flexibility is highly evident in the Forging case study. […]