BACKGROUND

Given its history in the automotive industry, ETMA is well-prepared to manufacture and increase the quality and innovation of its parts to its clients. Therefore, the case study presented here is revealing of the way ETMA faces each challenge.

In fact, one of its added values is the technical cooperation between all the areas involved in the development of a part, in order to be operational for the client, achievable for ETMA and, obviously, more efficient and economic for both parties.

THE CHALLENGE

Within this context, and as a result of a business and trustworthy relationship with more than 30 years, ETMA was contacted by one of its automotive industry clients in order to present a proposal for the development of a connecting rod – a specific part which would be used in a car braking system.

Although several other projects had already been developed for this client, this time, the challenge was different, because the part to be developed was complex and did not integrate ETMA’s portfolio.

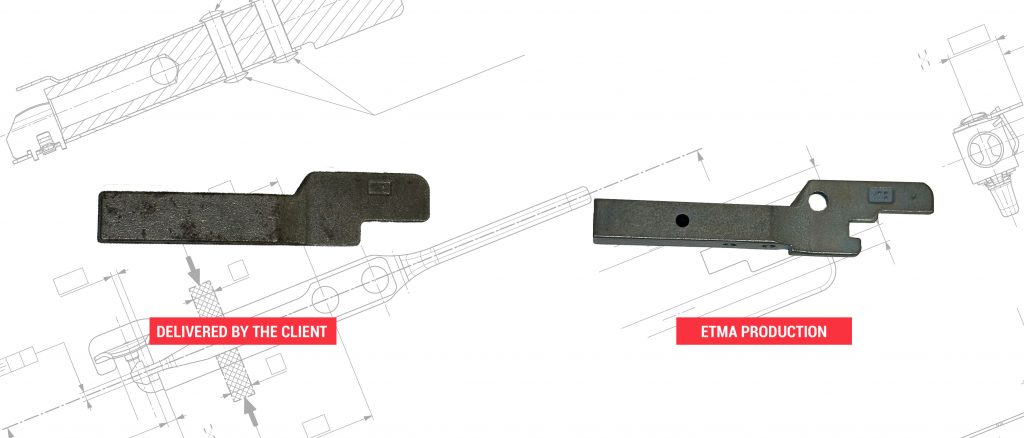

This steel part was hot forged and included a complexity in terms of the operations it entailed, which demanded many operation and fastening plans for the part, with different critical features.

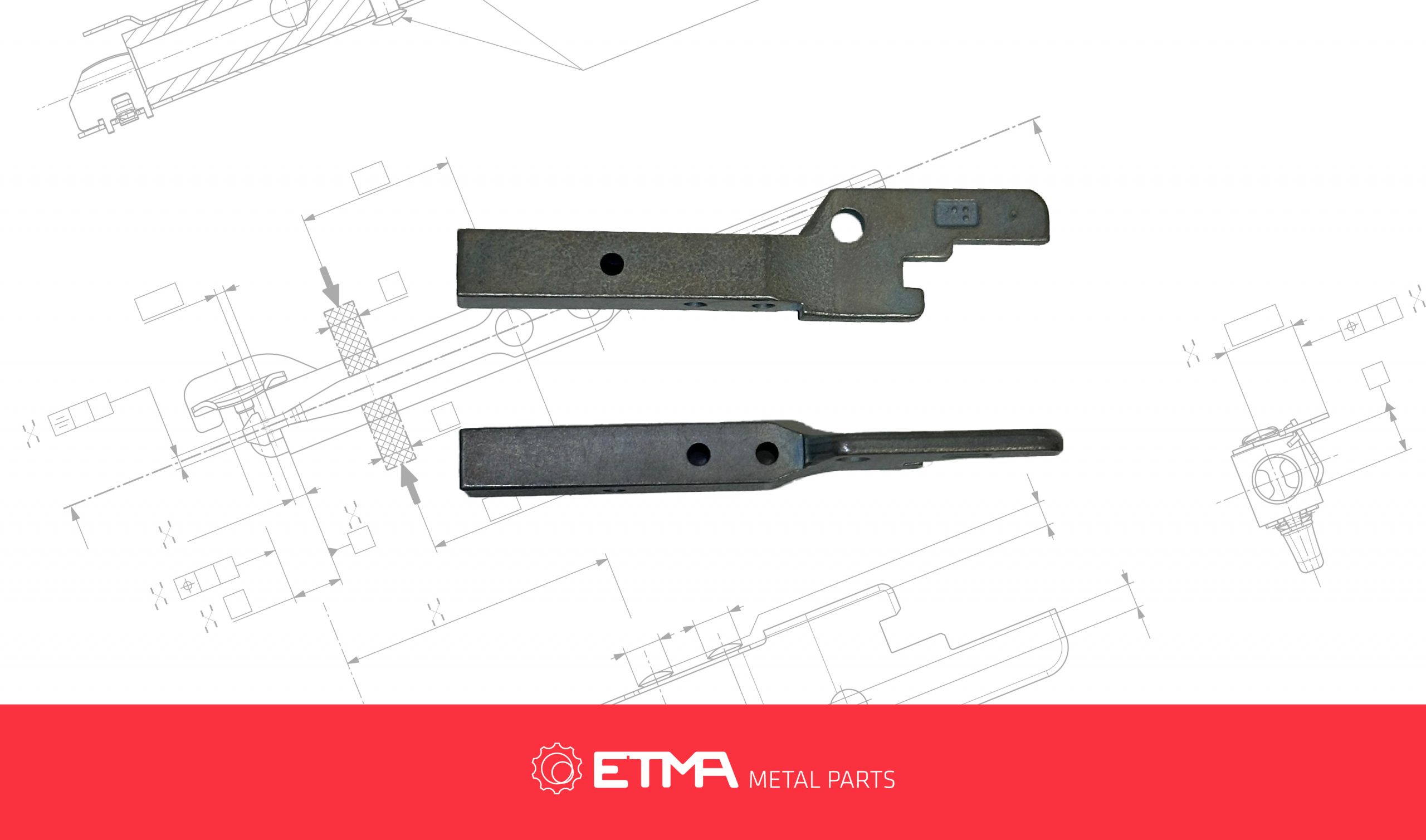

THE PART

This connecting rod is assembled in a car braking system. It integrates the subsystem responsible for the automatic wear adjustment, therefore, ensuring its reliability, in other words, preserving the level of performance despite the inevitable wear of the braking system.

The main braking system consists of dissipating the kinetic energy of the vehicle, transforming it into heat, which is translated into speed reduction or stoppage of the vehicle. In this process, two different configurations are generally used: disc brakes or drums. In this specific case, this is a drum system.

Regardless of the type of braking system used, it is necessary that it is strong and reliable. This way, it is mandatory that the braking system is able to respond, even if a leak occurs.

THE DEVELOPMENT OF THE PROJECT

Therefore, we were in the presence of a part which was not only important to the car braking system, but also challenging in terms of its manufacturing process.

This project involved 4 of ETMA’s 10 integrated production processes:

- Stamping – to shape the external contour starting from the part coming from the hot forging;

- 2 machining processes – to provide it flat surfaces of low roughness and precise holes in terms of dimensions and geometry;

- Tools and equipment – to plan and manufacture the fastening tools and devices used, to adapt the equipment to the operations needed to manufacture, and to plan and operationalise a 100% automatic inspection system.

- Galvanic coatings – for the surface finish of the part and corrosion protection through the application of a layer of zinc/nickel alloy.

Regarding milling, one of the machines was entirely produced by ETMA, and a second machine was adapted from an existing one. This was a complex machine, a kind of transfer machine, with several workstations and a capacity for several continuous operations in each part.

In terms of quality system, ETMA has also developed an automatic inspection machine of the part for this project.

PARTICIPATION OF SEVERAL TECHNICAL TEAMS

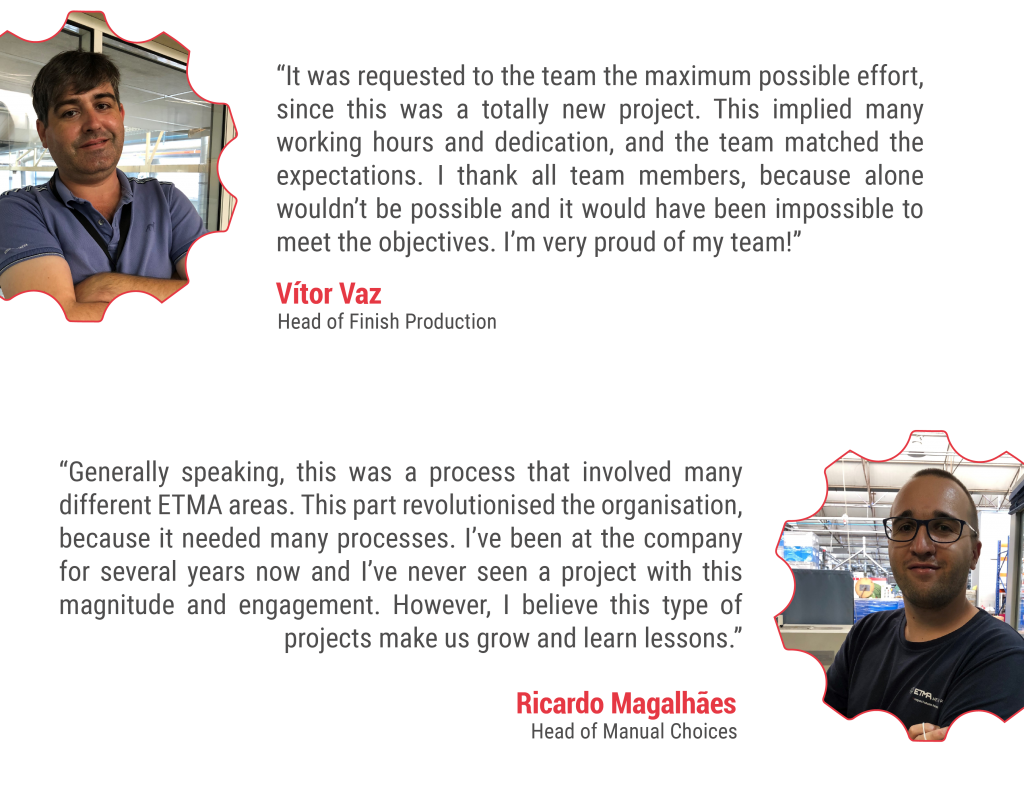

Regarding the teams assigned to this project, almost every ETMA’s technical team was involved, such as: the Stamping team (including the team of stamping tool projects), the Turning team for the milling process, the R&D Department, among other areas which helped to adapt the new machine and its respective installation. All technical areas were led by the Project Management team.

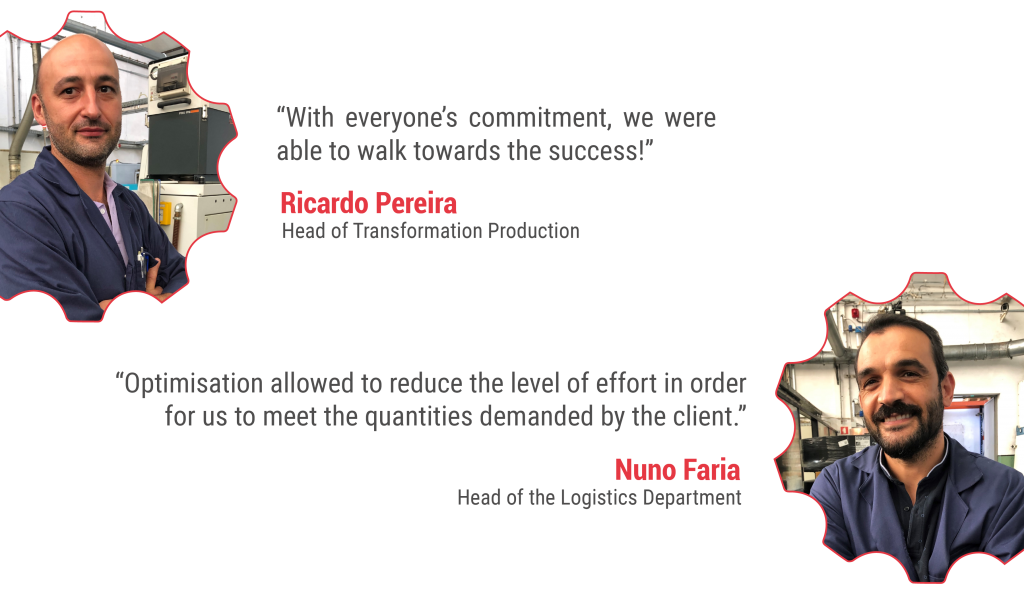

This was a challenging, complicated and complex process, with many subprocesses involved, and from which several learnings and lessons were taught. Today, ETMA can state this was a winning investment, as a result of the huge commitment of all the teams involved.

Here are the statements of some of those in charge of the respective teams involved in this project:

THE ADVANTAGE OF HAVING ETMA AS A PARTNER

The results obtained lived up to the expectations of both parts, once more showcasing that ETMA, through its innovation, development, expertise, flexibility, engagement and commitment, fulfils its mission of adding value to its clients.

The constant technical, technological and human capacity to adapt to the client’s demands, as well as the effort showed by the teams in which the new projects were organised, up to the solving of the problems presented, make ETMA to always try to exceed the client’s expectations, through the provision of added value services, supported by flexible and innovative solutions.

CONCLUSION

The case study presented here is revealing of the way ETMA faces each project. More than just producing metal parts based on the specificities provided by the client, ETMA offer support and technical capacity in the development of each product, even before its industrialisation.

Therefore, ETMA’s mission aims to respond to the challenges presented by its clients, offering the specialised technical support needed for the development of the parts through its 10 Integrated Production Process System. A winning investment that also ensures the quality of the development from the project to the final product and to which we join:

- The great ETMA’s know-how in the metallurgy and metalworking sectors (84 years);

- The high experience in the most different activity sectors: automotive, electrical, home appliances, plastic injection/overmoulding, fastening, among others);

- A qualified technical team, with a continuous improvement concern;

- Certifications in the ISO 9001, IATF 16949 and ISO 14001 standards.

If you have a new project to develop and/or are looking for the best alternative to an already existing project, ETMA is available to collaborate and help you find the best answer.

We are convinced that we can help! Contact us: marketing@etmametalparts.com