BACKGROUND

Over the last decade, ETMA has been demonstrating in the market its high capacity and technical know-how in response to the demanding sector of bicycles, mopeds, motorcycles and their components.

Proof of this is the various types of parts already produced by the company for this business area, one of which we will present in this article.

THE CHALLENGE

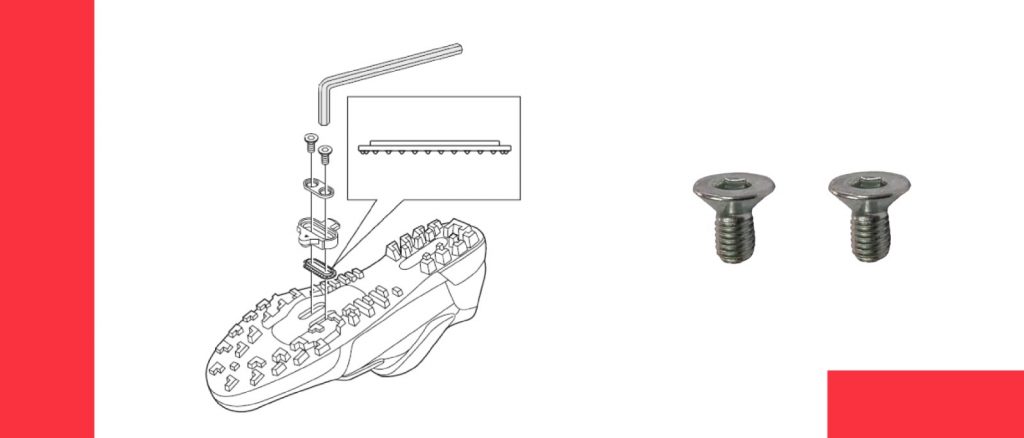

ETMA was contacted by a European supplier in order to present a competitive solution for the production of a very specific screw for the fastening of rails for automatic cycling pedals.

It should be noted that automatic pedals are currently a very popular choice among professional and amateur cyclists, as they allow a more robust and efficient power transmission. Thanks to their stable and flexible platform, easy operation and long-lasting performance, they also allow the shoe to be released more quickly than traditional cleat rails. As a result, the level of demand for the manufacture of these components is also increasing.

In this specific case, regarding the screws produced by ETMA, two units are applied to each rail, which is responsible for transmitting the energy that the cyclist is using to make the bicycle move.

Although these are relatively simple parts to produce, geometrically speaking, the challenge was to present the client with a solution for additional treatments that would make the part as resistant as possible, both in terms of mechanics and wear, as well as oxidation resistance.

THE DEVELOPMENT OF THE PROJECT

Therefore, and in the first phase, based on the requirements presented by the client, ETMA developed the part in steel wire for 23B2 cold forging, in which the following production processes were contemplated:

- Cold forging (Carlo Salvi RF 550)

- Surface treatment: zinc

- Heat treatment

For this specific project, we can add that the secret was mainly the heat treatment applied to the screw.

THE ADDED VALUE OF HIRING ETMA

Aware of the evolution of the two-wheeler sector and its level of demand, whether for simpler projects or those requiring greater complexity, ETMA presents itself in the market with the competitive advantage of its exclusive system of 10 Integrated Production Processes, which allows it to offer in-house solutions with customised manufacturing, so that the parts fulfil the function for which they were designed and, therefore, can also be produced with the maximum level of efficiency.

CONCLUSION

The case study presented here is another example of how ETMA faces each of the projects it is entrusted with.

In this specific case, in addition to the competitive solution presented to the client, resulting from the company’s vast know-how in the development of this type of parts for decades now, ETMA’s capacity to develop less complex parts in terms of manufacture, but more demanding in terms of other technical requirements, was also demonstrated.

As a result of its innovation and development support dynamics, ETMA is also available to the two-wheeler market for the study of new products.

If you have a new project to develop and are looking for the best solution or if you require an alternative to an already existing project, ETMA is available to collaborate and help you find the best answer.

We are convinced that we can help! Contact us: marketing@etmametalparts.com