Thanks to the heavy investment ETMA has been making in the last decades in the expansion of its business areas, the company offers today a significant portfolio in the production of metal parts for several home appliances. And just like in any other sector, the company’s goal is still to develop solutions adjusted to the specificities of each product, with the permanent support of a dedicated and highly qualified technical team.

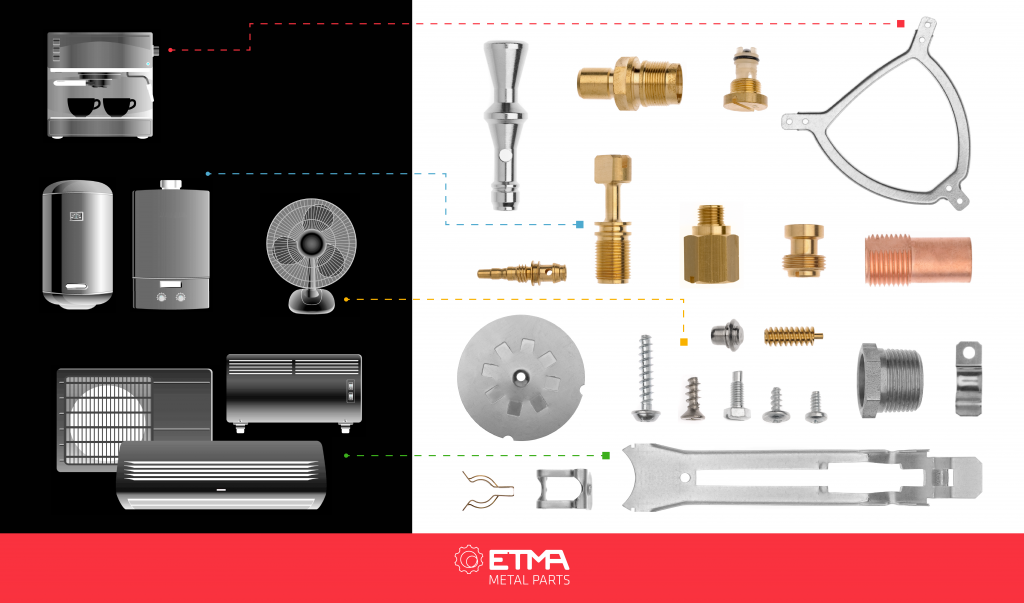

Coffee machines, water heaters, boilers, kitchen robots, and others are among the small and medium-sized home appliances for which ETMA produces components are.

PARTS CUSTOMISED TO FIT THE NEEDS OF THE CLIENT

ETMA offers the market the competitive advantage of its unique 10 Integrated Production Process system, which allows to keep track of the customised production of the parts right from the project stage, in order for them to fulfil the function they were designed for, as well as to produce them with the highest efficiency level.

Connectors, connection terminals, rotation shafts and rivets, flat springs, flow control parts are just some of the many examples of parts produced by ETMA for the home appliances sector, as can be seen from the following image:

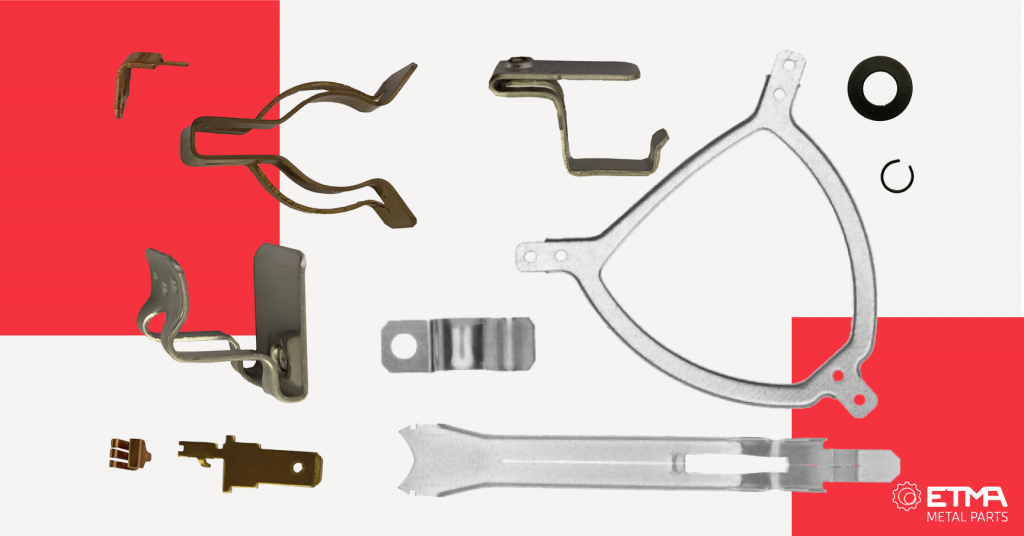

ETMA’S EXPERTISE IN SPRINGS AND CONNECTORS

ETMA’s broad experience with this type of components allows to obtain the geometry intended by the client that, however complicated it may be, ETMA is capable of prototyping, testing and validating or optimizing, not only the component’s function, but also its production process, offering an economic advantage to the client.

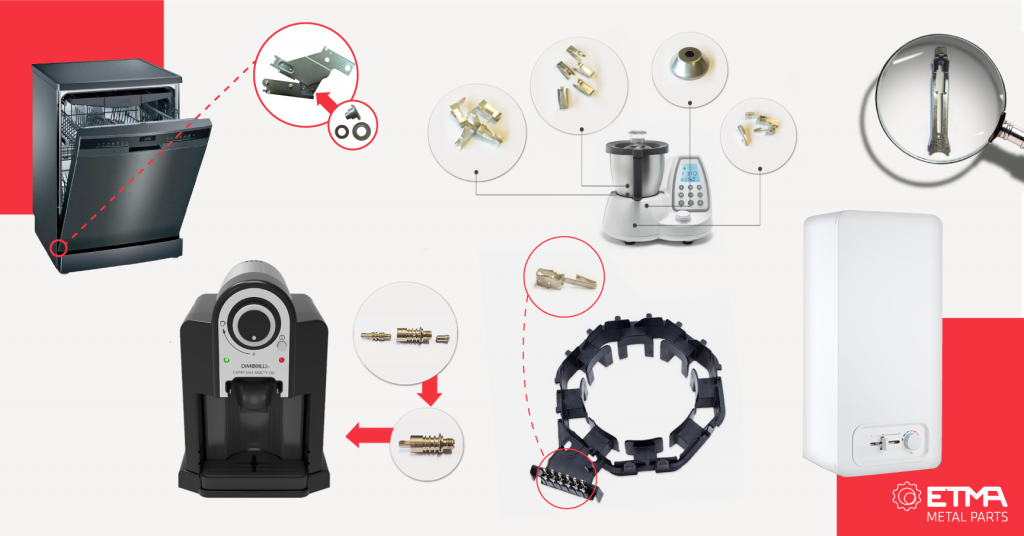

ASSEMBLY CAPACITY

Besides producing metal parts for the home appliances sector, ETMA develops integrated solutions adjusted to the specificities of each product, resorting to more than one production process to achieve the finished product. But that’s not all, the company also offers the ability to assemble these same parts, whether it is into plastic or metal components.

SOME REFERENCE WORTHY CLIENTS

ETMA is proud to have, in its portfolio, national and worldwide reference clients of the home appliances market, among which:

The 10 Integrated Production Process system offers a great number of advantages for the client, namely:

- Greater control of the processes and their interaction and, consequently, greater flexibility;

- Reduced lead times, as the processes and its treatments are performed indoor;

- Reduction of logistics costs;

- Optimisation of product specifications;

- Reduction of quality costs;

- Reduction of production costs;

- Diversified know-how covering different skills.

In conclusion, the experience built up over the years allows ETMA to understand the needs of each client and study and test beforehand the interconnection of the productive processes that will be involved.