In the last decade, ETMA has experienced a very strong growth in the production of metallic parts for the automotive sector, placing itself, in the production chain, at TIER 2 and TIER 3 levels. This rapid development also reflects the company’s growing commitment to technical and human know-how and in equipment and technology.

The entire organization is certified by international standards, so important and decisive for this sector, such as IATF 16949:2016 and ISO 9001:2015. A guarantee of the quality of the parts produced by ETMA, which is also supported by a quality management system, managed by a specialized team, through its Quality Department.

Step by step, conquest by conquest, client by client, project by project, ETMA continues to grow within this business area, always with a strong bet on quality and rigor and focus on continuous improvement. The trust gained from each client is a reflection of the results of audits carried out by the clients themselves.

PARTS CUSTOMISED TO FIT THE NEEDS OF THE CLIENT

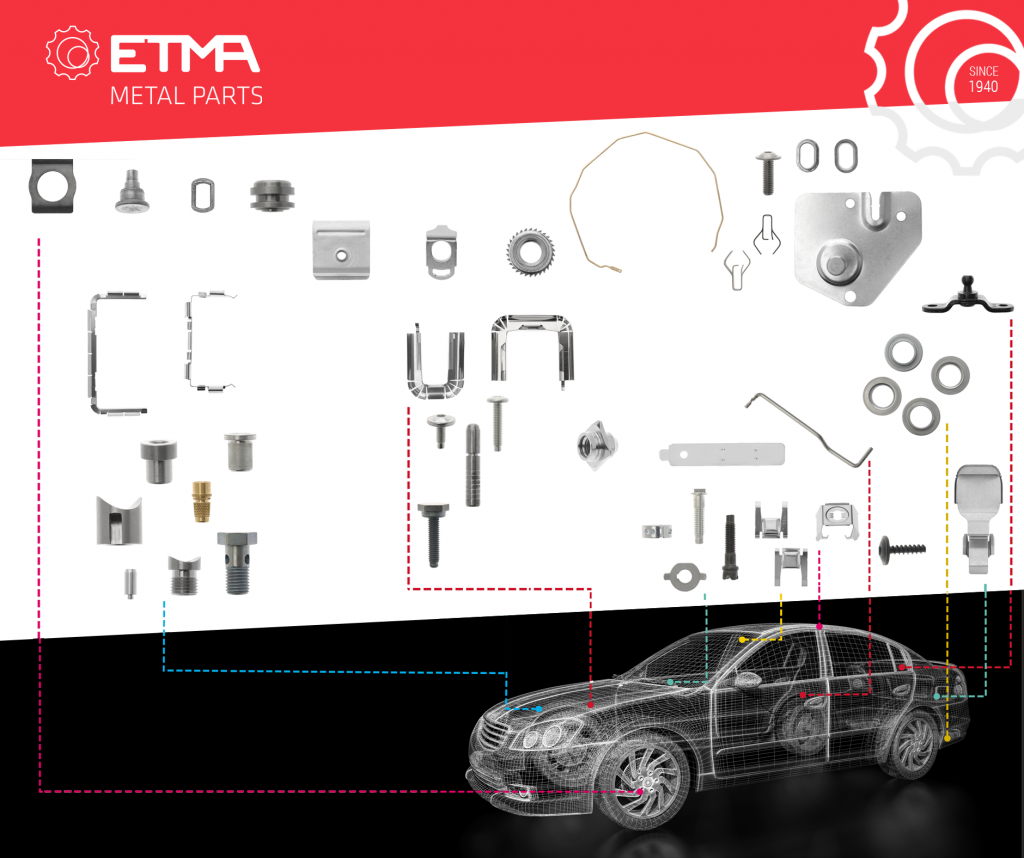

Due to the fact that ETMA presents itself in the market with several production processes, it allows it to respond to the production of a wide range of products. For this reason, facing a very specific business area, such as the automotive sector, ETMA is not a specialist only in a specific part, but in a wide range variety of parts that make up a car, of which the following stand out:

- Brakes

- Engines

- Ceilings

- Seats

- Plastic components

- Etc.

Among these pieces are:

- High strength screws

- Components for brakes

- Panel fixing

- Injection parts

- Circuits for headlights

- Etc.

It should be noted that in the development of each project, there is always a great involvement and partnership on the part of ETMA with each client.

ASSEMBLY CAPACITY

Depending on each project, ETMA has the technical capacity and know-how necessary to develop integrated solutions, adjusted to the specifics of each product.

In this sense, using more than one production process to obtain the finished product, ETMA not only develops the equipment and produces the parts, but also adds the internal capacity to assemble the parts, whether in metallic or plastic components.

Some examples that reflect this assembly capability:

SOME REFERENCE WORTHY CLIENTS

ETMA is proud to have, in its portfolio, national and worldwide reference clients of the home appliances market, among which:

The 10 Integrated Production Process system offers a great number of advantages for the client, namely:

- Greater control of the processes and their interaction and, consequently, greater flexibility;

- Reduced lead times, as the processes and its treatments are performed indoor;

- Reduction of logistics costs;

- Optimisation of product specifications;

- Reduction of quality costs;

- Reduction of production costs;

- Diversified know-how covering different skills.

In conclusion, the experience built up over the years allows ETMA to understand the needs of each client and study and test beforehand the interconnection of the productive processes that will be involved.