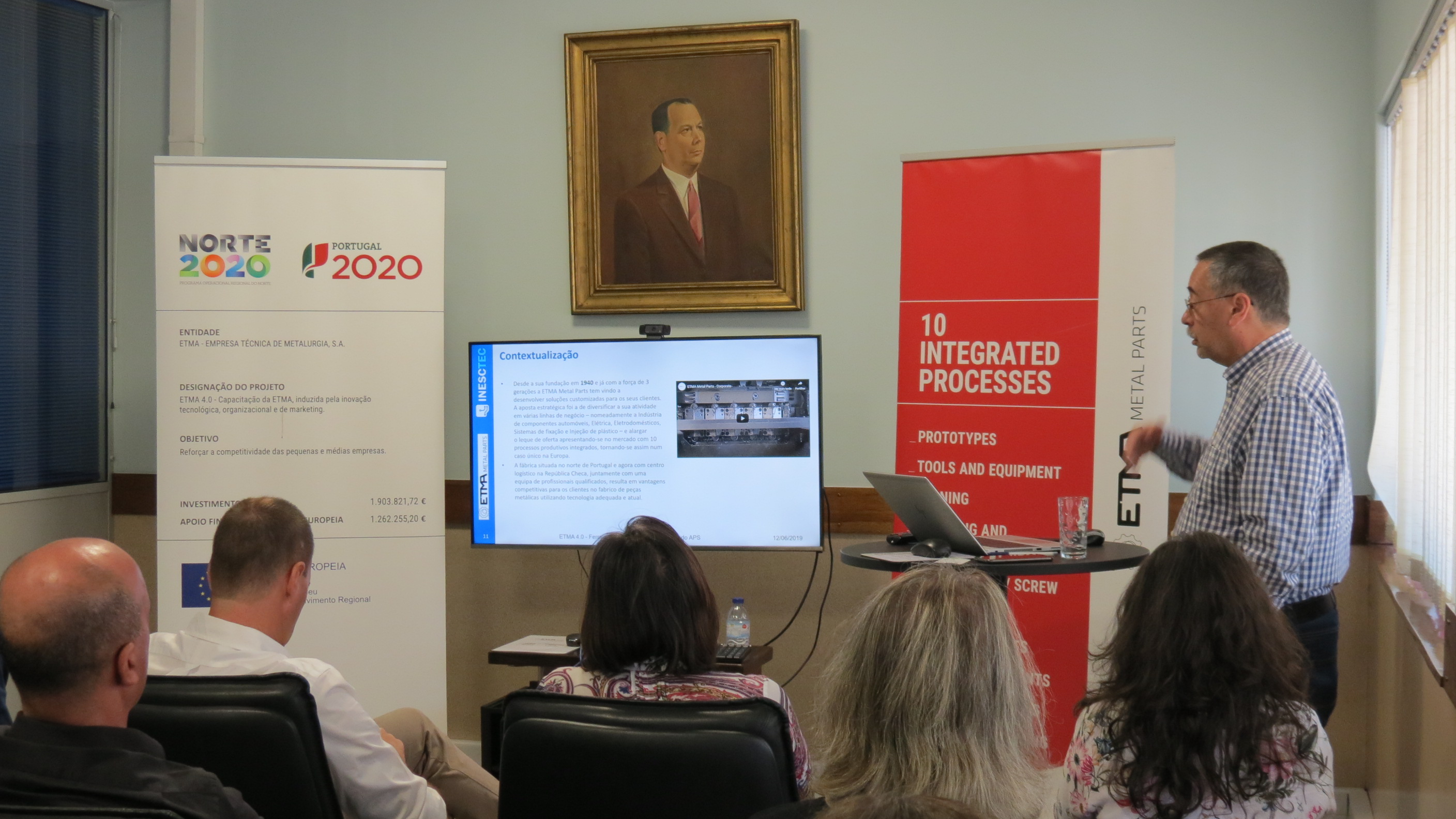

Improve production operations in order to respond, in a timely manner, to client requests is one of the greatest goals of the new advanced planning APS solution, presented on 12 June at Open Day, an event whose theme was “ETMA 4.0 – advanced planning APS tool”.

António Correia Alves, from INESC TEC – Institute for Systems and Computer Engineering, Technology and Science, presented a description of ETMA’s business model, its production system and the way different components of the ecosystem are organised. Additionally, he explained the advantages that the APS tool will bring to the company’s operational management and its impact on customer service.

This new solution, whose engine optimisation was developed at INESC TEC, aims to improve raw material management, adopting more suitable supply policies that result in the reduction of inventory maintenance costs, while simultaneously reducing material failure situations.

The goals of this productive innovation project are to support the company in the implementation of an ERP solution – in the Internal Logistics and Production areas – as well as the implementation of an IIoT platform.

Mário António Braga, ETMA’s CEO, took the opportunity to emphasise that the investment in innovation has been one of the company’s greatest strategic objectives. “The last two years have shown a 20% growth. Our goal is constant improvement and innovation, crucial aspects for the areas of metallurgy and metalworking. We have grown in sales and in something that, for me, is even more relevant, in the number of employees. ETMA is proud to create jobs”, he concluded.

On Open Day, the event that brought together ETMA’s material and service suppliers, the ongoing operational reorganisation initiatives, procedures that will allow an improvement in the company’s supply chain integration, were also presented. It was possible to see some of the presented methodologies during the visit to the factory.

This initiative was carried out within the scope of the SI Inovação Produtiva project, co-funded by the Norte 2020 programme, in the context of funding provided by the Portugal 2020 programme and the European Regional Development Fund.

Co-financed by: