Internal audits are crucial to any organization that wants to grow and perform efficient internal processes. With ETMA, this is no different – especially because it considers auditing to be a key part of its continuous improvement process.

Thus, in an increasingly competitive market, performing internal audits will bring many benefits as a result of the following steps that are a part of this process:

- Observe, measure, and assess the risks and controls of the company;

- Ensure that the company is compliant with policies and laws;

- Suggest improvements through the results achieved.

However, ETMA goes beyond just performing mandatory audits. It has been implementing its own internal audit system, which is 100% digital and seamless. Although not obligated to do this, ETMA finds it essential in ensuring its compliance with the established requirements so as to reduce the number of errors and take immediate action.

PDCA CYCLE

Having the Plan–Do–Check–Act cycle as its foundation, ETMA is able to identify the issues that need improvement and apply the necessary corrections through an action plan.

According to Luís Gomes, Director of the Production Quality Department: “in terms of the results achieved, and at a global level, we have seen how ETMA and its processes are well-prepared, meeting the requirements.”

100% ETMA TEAM – QUALITY

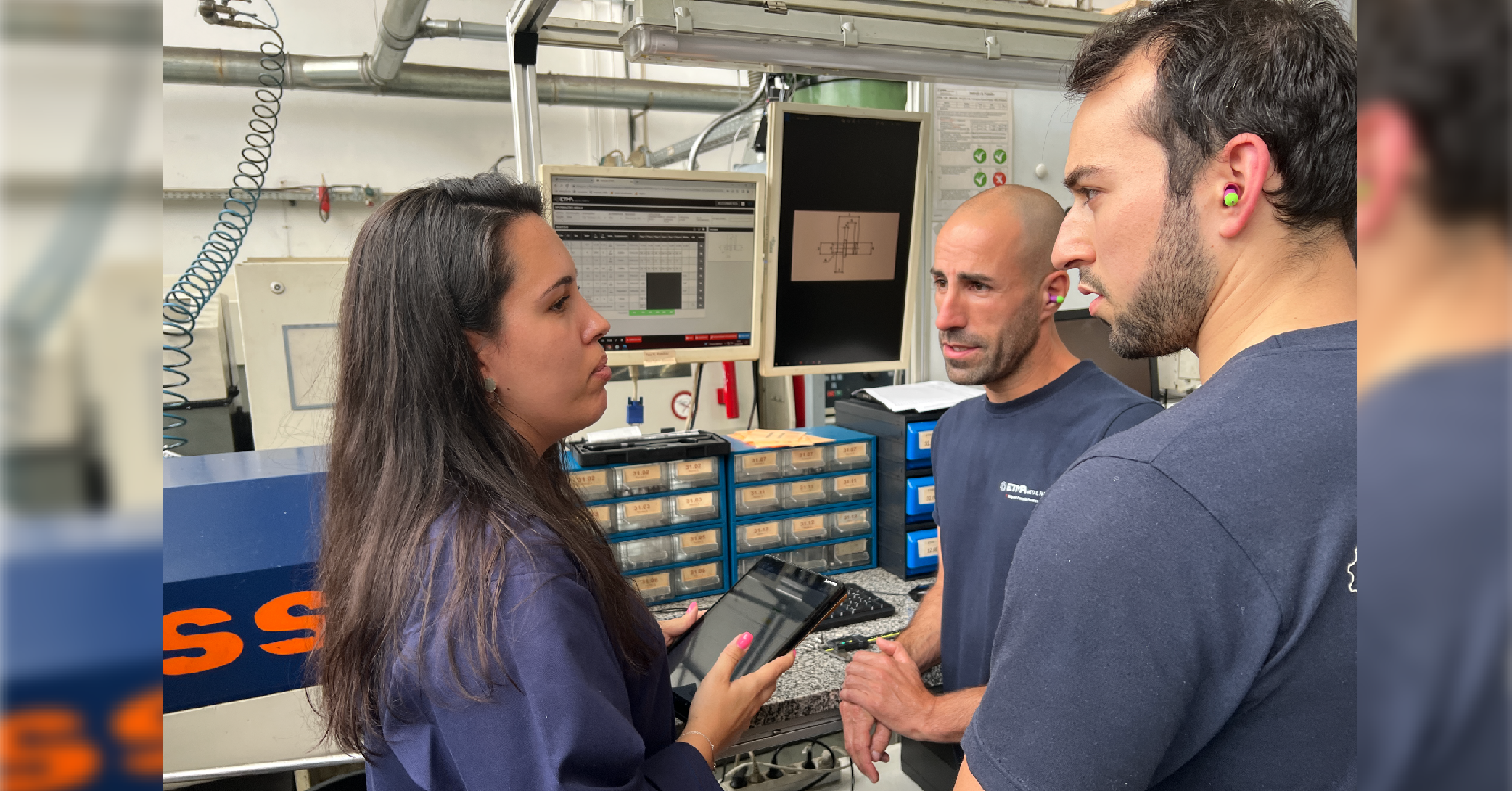

It is thanks to this background that the company managed to also create the “100% ETMA TEAM – QUALITY” dynamic, precisely with the goal of promoting a spirit of continuous improvement along with its employees in different contexts. The purpose is to challenge the teams in a healthy corporate and competitive environment, motivating them to improve their performance.

This dynamic consists of challenging all areas (through Kaizen teams) to carry out all procedures previously established by the Quality department. The teams are then audited by an internal group (auditors) that will be responsible for recording each team’s performance.

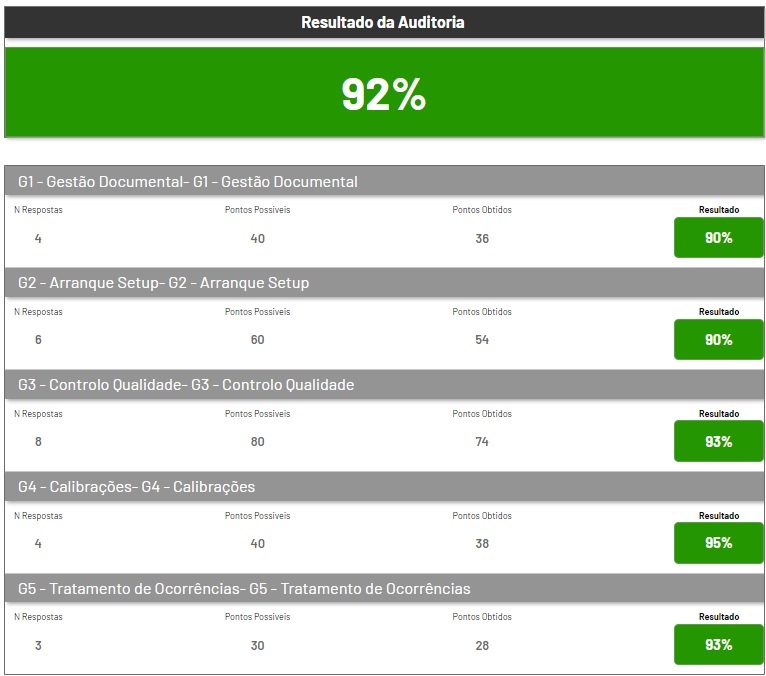

These internal audits will be assessed in the following manner:

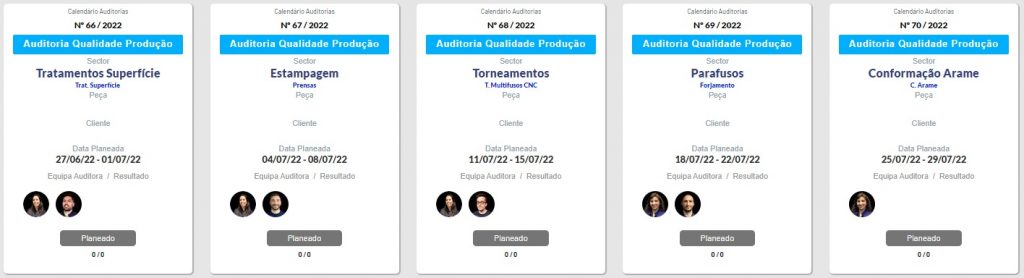

- Weekly audits of all production areas, with results shared internally each month;

- The internal team (auditors) will be guided by the Team Leader of the area being audited;

- The score is calculated using the cumulative average of the audits performed;

- The maximum score for each question is 10, which means that those who score below this amount will have to do an action plan;

- The audit schedule will be shared every month, in addition to the results of the previous months and the action plans to be implemented;

- The team closest to a score of 100% will be awarded.

With this customized concept and through internal tools, ETMA manages to apply continuous improvement to its processes, to reduce the number of errors and take immediate action anytime there are deviations.

Values such as Innovation and Flexibility are always part of the company, which stays true to the 3 pillars that support the business: