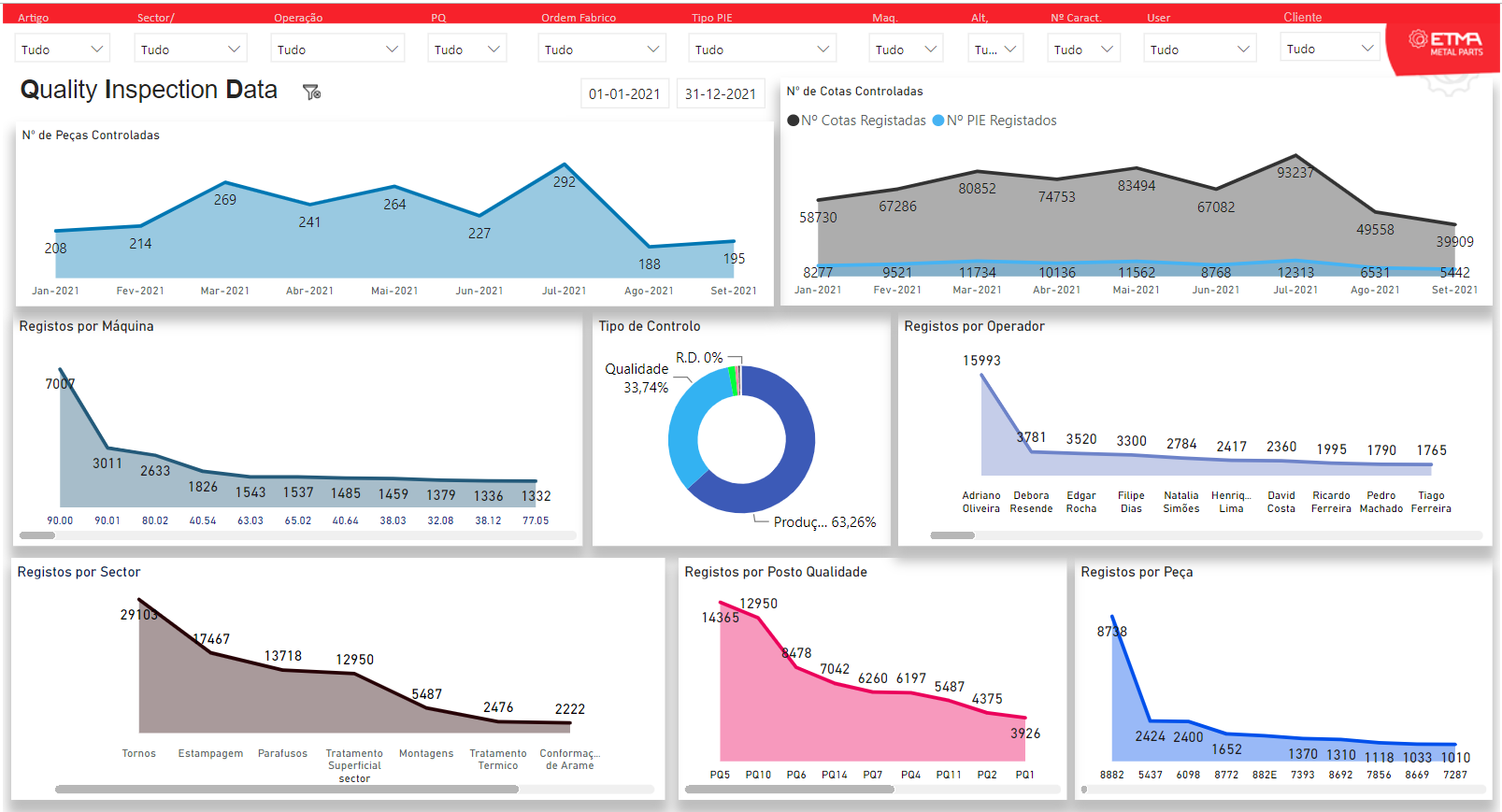

As part of the mandatory control of the quality records of its production processes, ETMA has developed and implemented its own Quality Control software, through which all inspection data are centralized with instant analysis.

Although the previous software used also helped to continuously improve and speed up the time for decision making, it was found that, in computer terms, the operators’ work was “quite heavy.” In other words, the information that was being extracted was not easy to obtain, and the system was also becoming outdated.

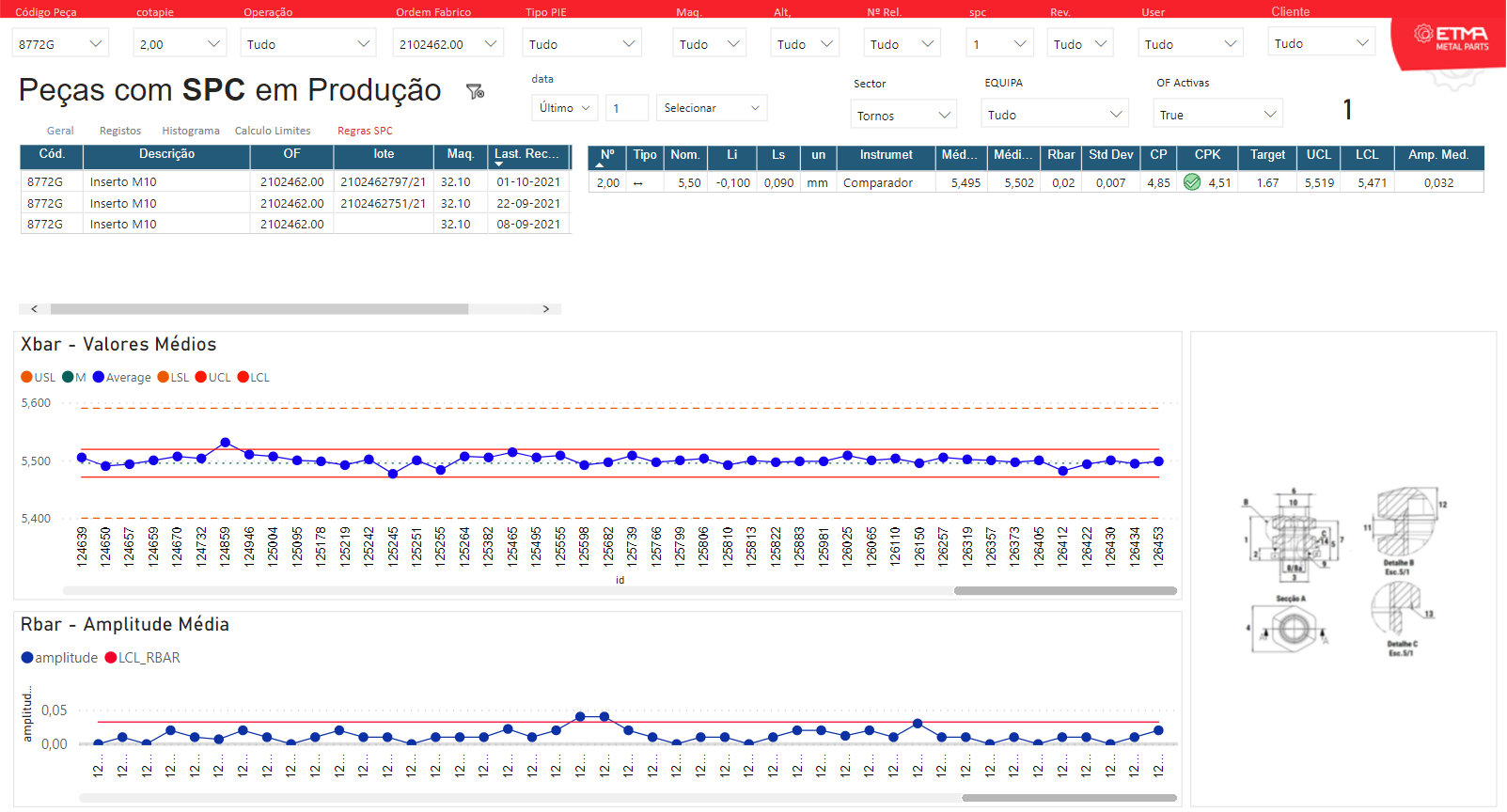

Given this scenario, ETMA decided to develop its own in-house Quality Control recording system, which is better suited to the company and its real needs and would respond better to customer expectations regarding traceability and production process capabilities.

Luís Gomes, head of the Production Quality Department and leader of the SRQ (ETMA’s Quality Records Software) development process, points out the main advantages of the system:

- Agility in the Control Process

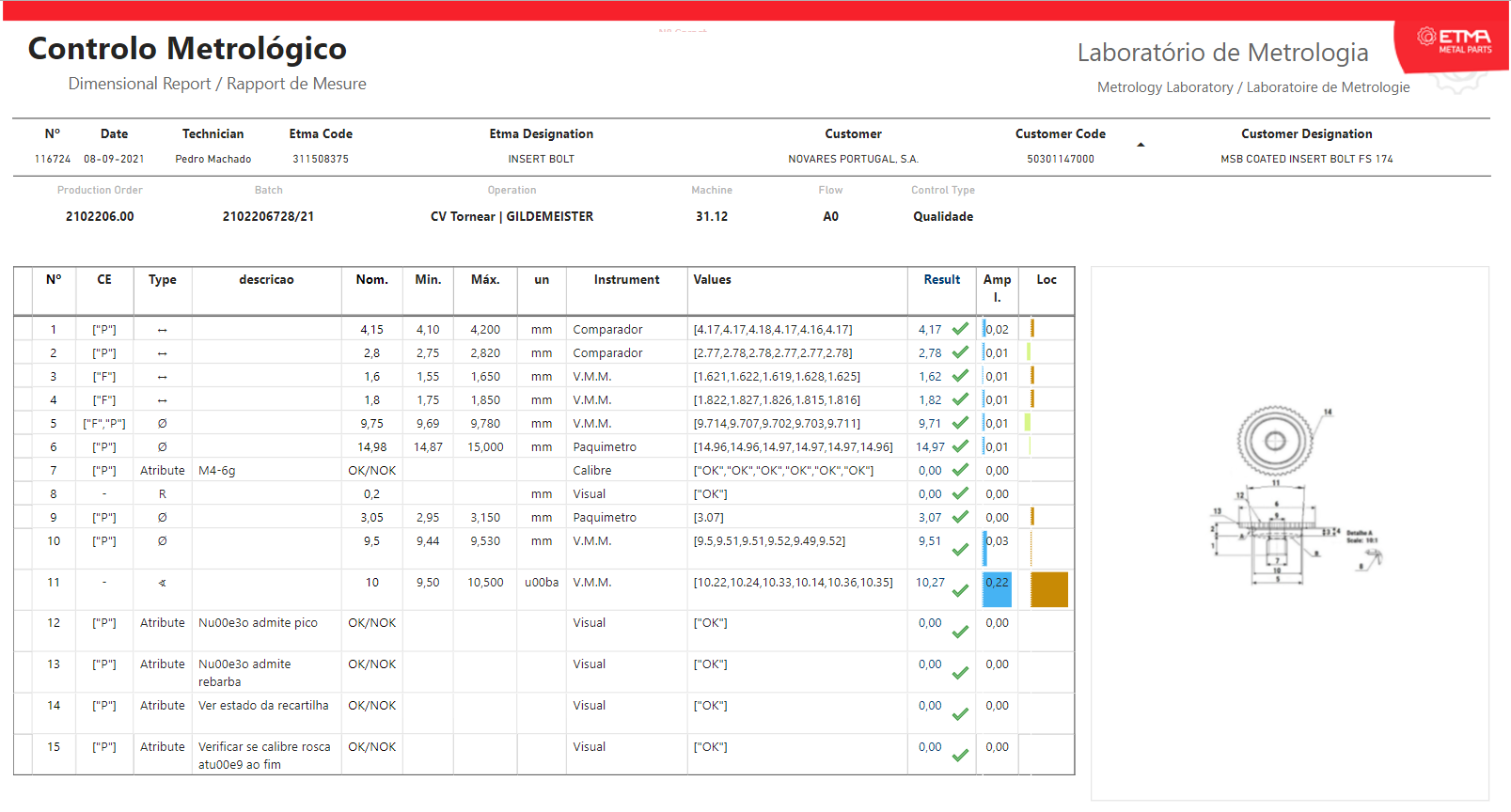

- Traceability

- Online quality control and SPC follow-up

- Simple and quick interpretation of the collected data

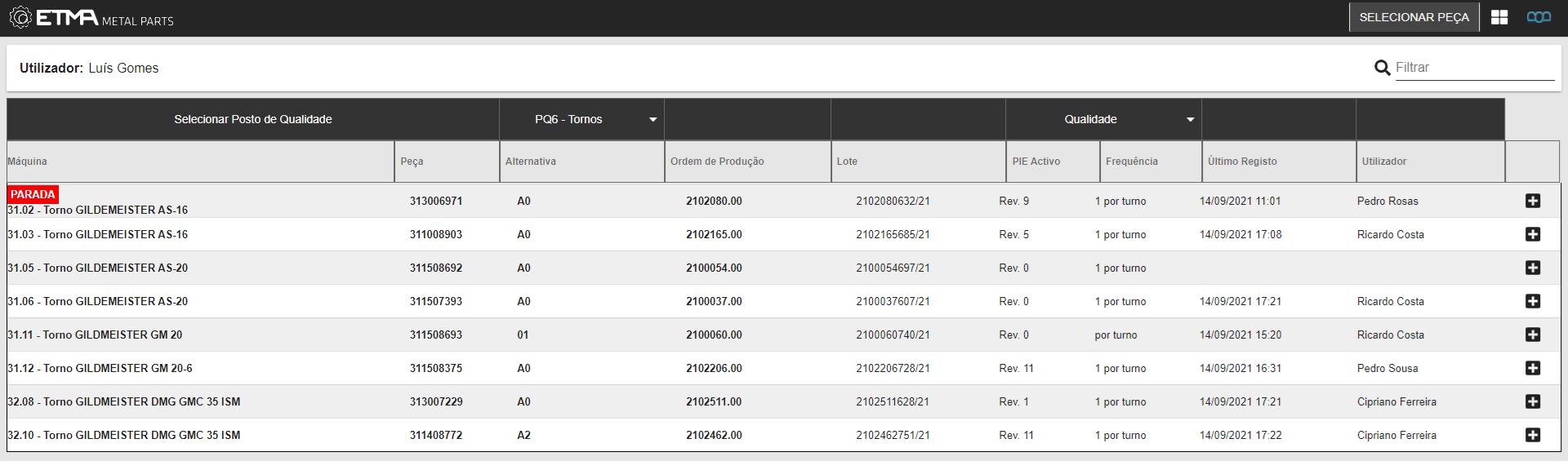

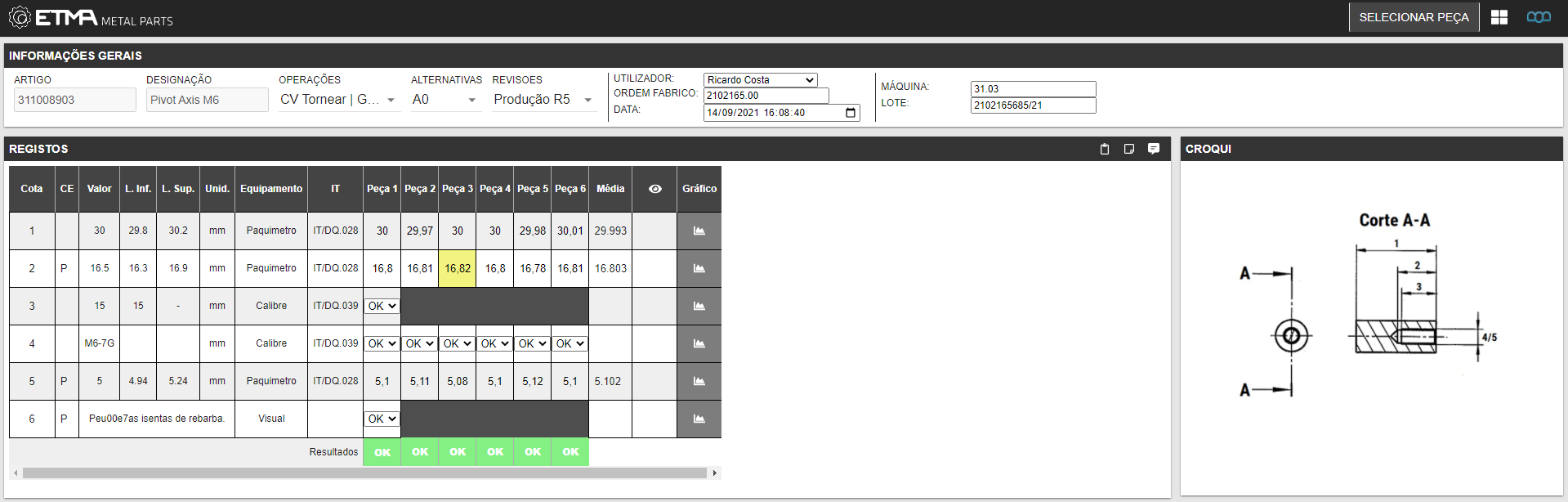

Thus, says Luís Gomes, “no operator needs to fill in absolutely anything about the part he is controlling, since all the necessary information is already pre-filled from the company’s ERP”. Luís also adds that this system “ensures greater security to the customer in terms of traceability, too.”

Therefore, “it is possible to ensure that the customer gets the information faster and with assured traceability”, while “the operator now only has to focus on the quality control, with zero risk of data entry errors.”

All information about the machine, parts, and batches is already pre-filled, ensuring fast quality control and traceability integrity.

Currently, through SRQ, “the definition of the Control Plan and the respective control PIEs are in the same computer platform and, when a change is needed, the process is automatic and does not require any parallel procedures,” says Luís Gomes.

SRQ also allows statistical process control and online production follow-up by analyzing the causes for the deviations and ensuring instant decision making. As mentioned by Luís Gomes, “SRQ can give us information, by sector, about which parts are having statistical control and if their levels are higher or lower than what was required by the customer, allowing immediate corrective actions.”

Another important aspect is that it is possible to monitor SPC online in production, analyze the causes for deviations and ensure decision making by following the control chart rules, according to the ISO 7870-2:2013 standard.

SRQ is yet another example of how ETMA prioritizes the customers and their needs. Customers are increasingly more demanding and rigorous, so the importance given to the issue of quality is a priority, and the company always strives for the maximum quality of the parts it produces in order to be at the forefront.

In this context, the ETMA team is already studying an evolution of this software, which, in the near future, will include the automatic export of machine measurements to SRQ. Soon, there will be more to come!