In ETMA Metal Parts production management is the centre of its strategy to continuously improve effectiveness. In this article it will be revealed the reason why ETMA adopted the Andon Boards (one of the tools used by Lean Manufacturing) as well as the benefits resulting from this production management strategy.

What is Andon Boards?

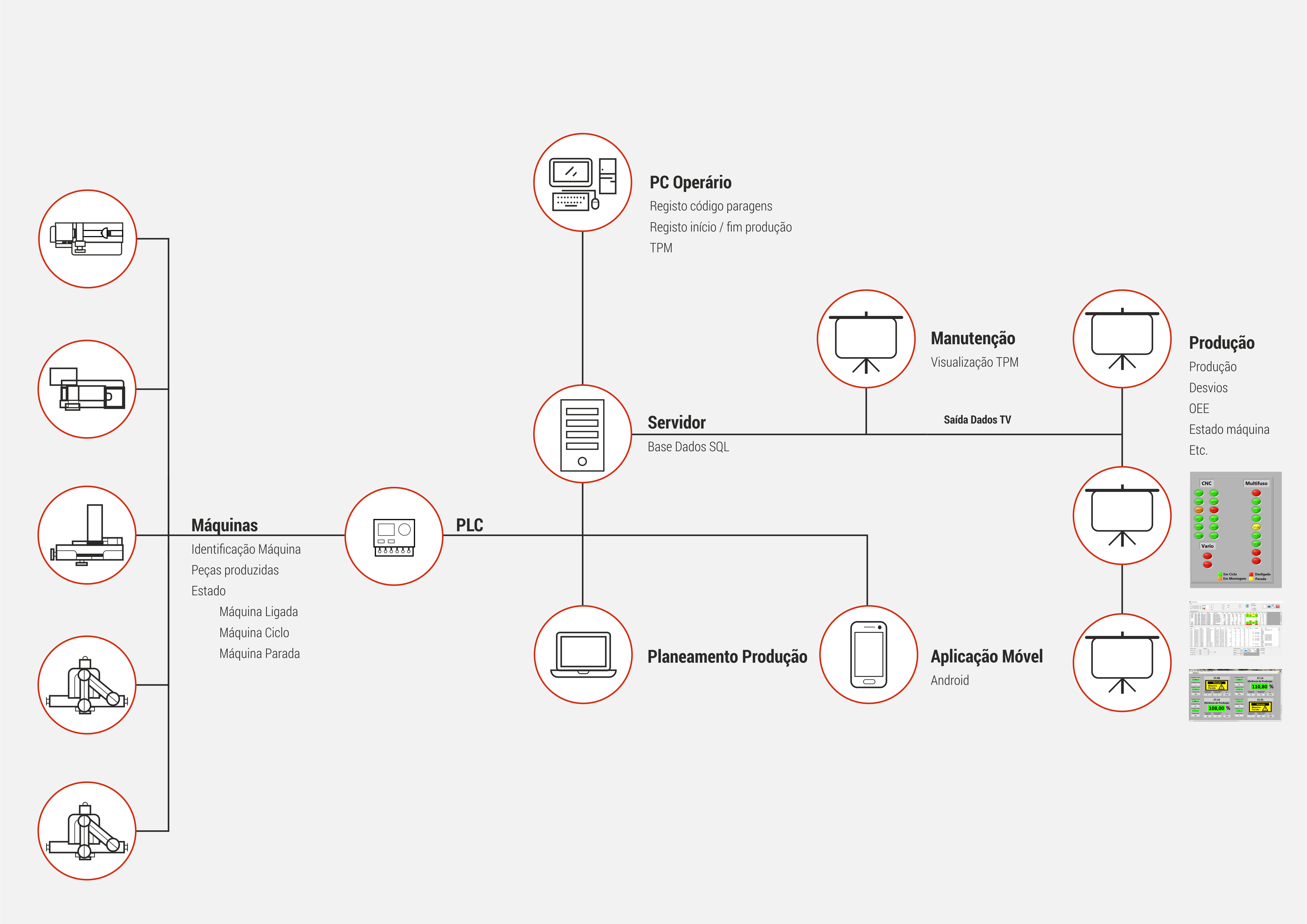

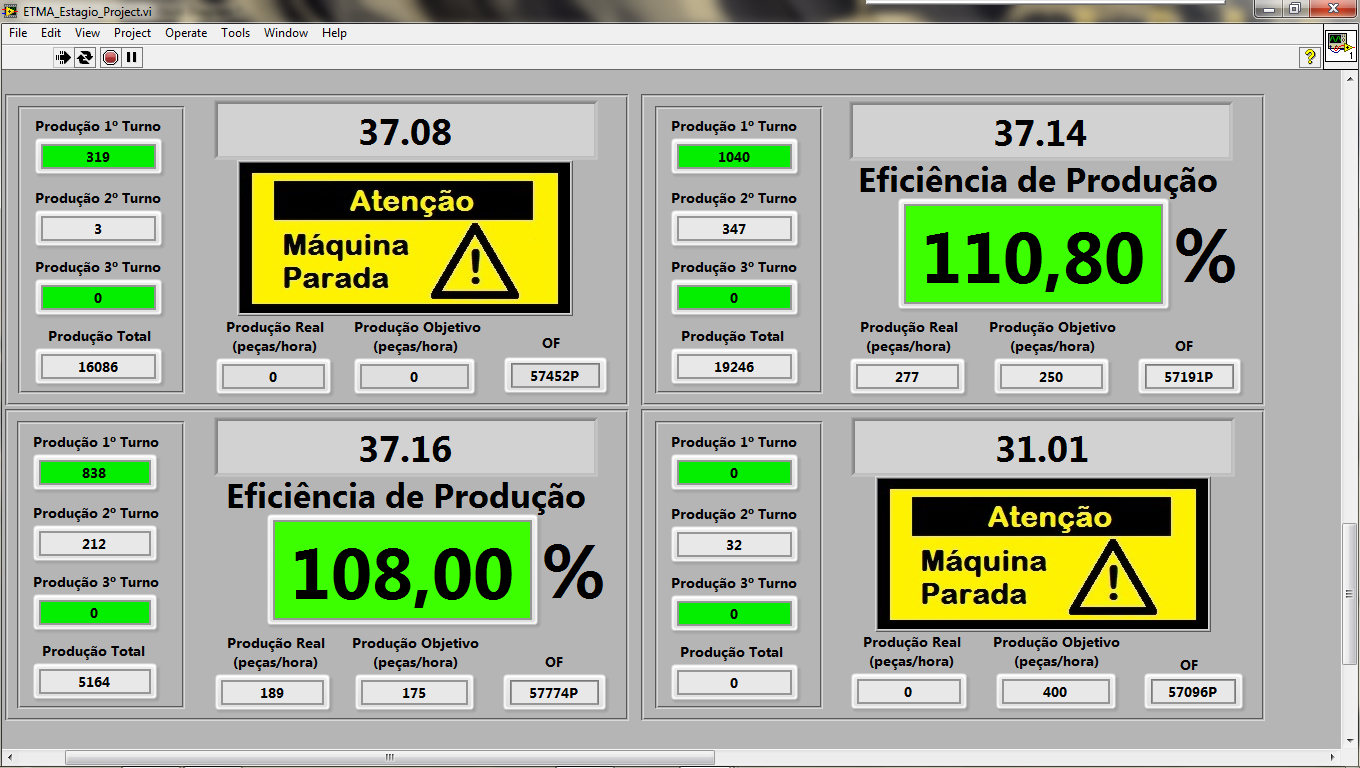

Andon Board is a tool whose function is to manage the production results and detect abnormal occurrencies. The biggest advantage of this tool is the ability to detect any abnormalities in the industrial processs and to fix problems. It is a method of visual management that signals problems in the production chain through audible alerts or visual notifications (such as boards; (message) alerts; visual signals).

Figure 1 – Andon Board Monitor

What are the benefits of using Andon Boards?

Firstly, it is important to underline the importance of visual management as a process for displaying critical information, such as performance indicators that are related to production, efficiency and quality.

By displaying this data in the production layout, every employee has a more precise idea of the production levels and tends to be more committed to high performance. Thus, visual management provides useful information, allowing supervisors and managers to better monitor performance and determine, in real time, the areas that need intervention.

Overall results help to increase productivity in all parts of the organization by increasing efficiency, quality and uptime.

Considering the unique nature of each project, making a profit on a specific production process depends on the ability of each team to reduce equipment setup times, as well as being able to maintain the production rate. Therefore, and in order to effectively achieve this goal, real-time information is needed to confirm that the goals defined during the production rate calculation are, in fact, being achieved.

What is the purpose of using Andon Boards?

By adopting the Andon Boards project, ETMA’s purpose is the optimization of the production control mode, as well as the analysis of production performance and the implementation of improvements in the company. In addition ETMA intends to demonstrate agility and creativity to adapt not only to its products, but also to its industrial management methods. ETMA’s ultimate goal with the Andon Boards project is to become more productive and competitive which will also benefit ETMA’s clients.

What are the results ETMA got from the Andon Boards project and what are the next steps?

ETMA is currently using this technique in the Turning and Stamping processes having already increased its productivity by 15%.

By the end of the year the company expects to apply this same technique in the Cold Forging process.

Being successful in a constantly evovlving world is ETMA’s mission.