ETMA has been growing considerably, both in production and turnover, and in technology and human resources. Following this evolution, and with the need to improve communication and quicker access to information, regarding fast problem-solving, the adoption of the Daily Kaizen method has proven to be the right choice.

A major ally for continuous improvement, this methodology is a simple and easy-to-apply tool, which helps at every level of production, where the most important factor is to raise the awareness of everyone, which is always necessary when striving for improvement, to achieve all the company’s goals, and to ensure client satisfaction with quality products and services.

ETMA’s management has been strengthened on a daily basis with the practice of Daily Kaizen, with visible results:

- In the improvement of communication and information sharing, allowing a higher commitment of the team;

- In daily dynamics, with the team informed about the daily priorities;

- In a more precise follow-up of indicators and profitability of production;

- In a faster reaction to problem-solving;

- In the promotion of the improvement cycle, through suggestions made by the employees.

And, it is precisely with the improvement suggestions made by the employees that ETMA was internally challenged to go further in the evolution of and efficient communication of teams, through the digitalisation of Daily Kaizen.

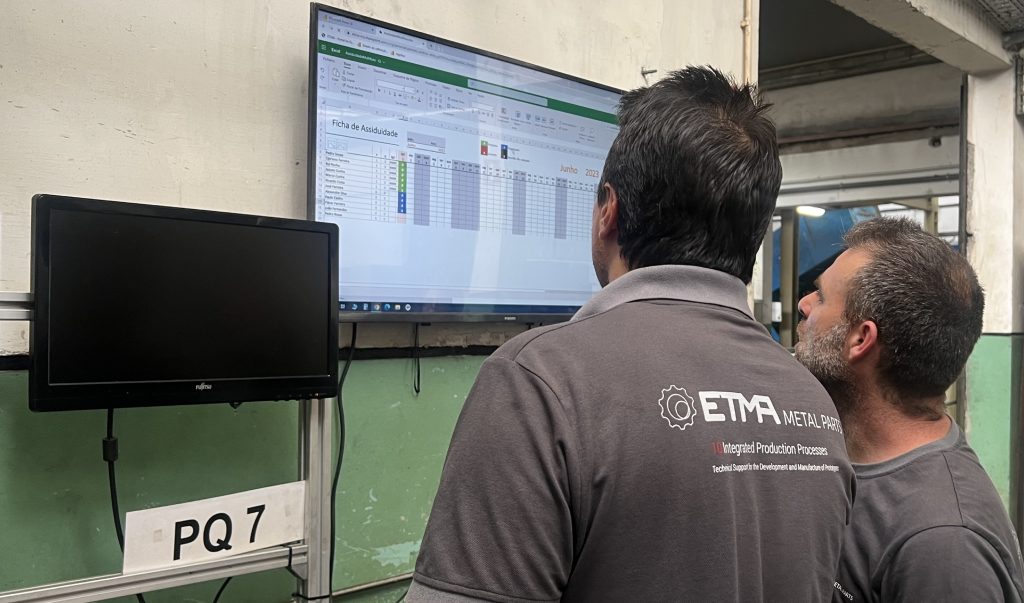

Within this context, last March, some teams began the Daily Kaizen meetings with access to a new digital format, developed by the Information Technology Department, which helped to speed up the access to information by each team and, through which, it is possible to access:

- Production indicators of each group of machines;

- Quality problems, both clients’ complaints and internally detected ROI;

- PDCA cycle for improvement register and control of each team;

- 5S audits performed by the teams;

- Work-related accidents in this area;

- Among other relevant topics.

According to Susana Agra, Director of the Human Resources Department and coordinator of Daily Kaizen at ETMA, “the investment in the digitalisation of Daily Kaizen essentially helps to avoid the duplication of work by the employees. The employees no longer need to fill in, repeatedly and manually, the indicators on the physical Kaizen boards, since this information already exists digitally and can be easily accessed through the respective monitors in each production sector”.

In this sense, since the information is already digitalised and its access is immediate, the procedures related to Daily Kaizen “become faster, saving physical space and time”. The Kaizen meetings continue to be held in person in each team, but now near the respective monitor, allowing “the consultation and discussion of the problems in a faster and more prompt way”, highlights Susana Agra.

As the person responsible for the information development of this new digital format, Gonçalo Cardoso, from the IT Department, also adds as an advantage the fact that “the information analysed is more reliable and clearer, with less failure probability”.

In turn, Hélder Gomes, responsible for the Turning section, highlights the “good reception by the teams” where this digitalisation has already been implemented. In addition to the “registered improvement in terms of productivity, a higher involvement of the teams in the meetings has also been visible” in the Daily Kaizen meetings.

The Daily Kaizen digitalisation is, therefore, another example that ETMA is internally equipped with technical know-how, which, on a daily basis, aims to contribute to a permanent investment in the innovation and development of continuous improvement methodologies.