This article has been used as a case study of the 10 integrated production process system that ETMA provides and that is unique in Europe. Learn briefly how ETMA promotes its projects, bringing from the very beginning all its experience and technical knowledge for the benefit of its clients.

Contextualisation

This client is one of the oldest and leading vehicle antenna specialists and manufacturers in the world. It has over 1000 employees all over eight facilities in Brazil, China, Germany, Mexico, Portugal and the USA.

Client’s request

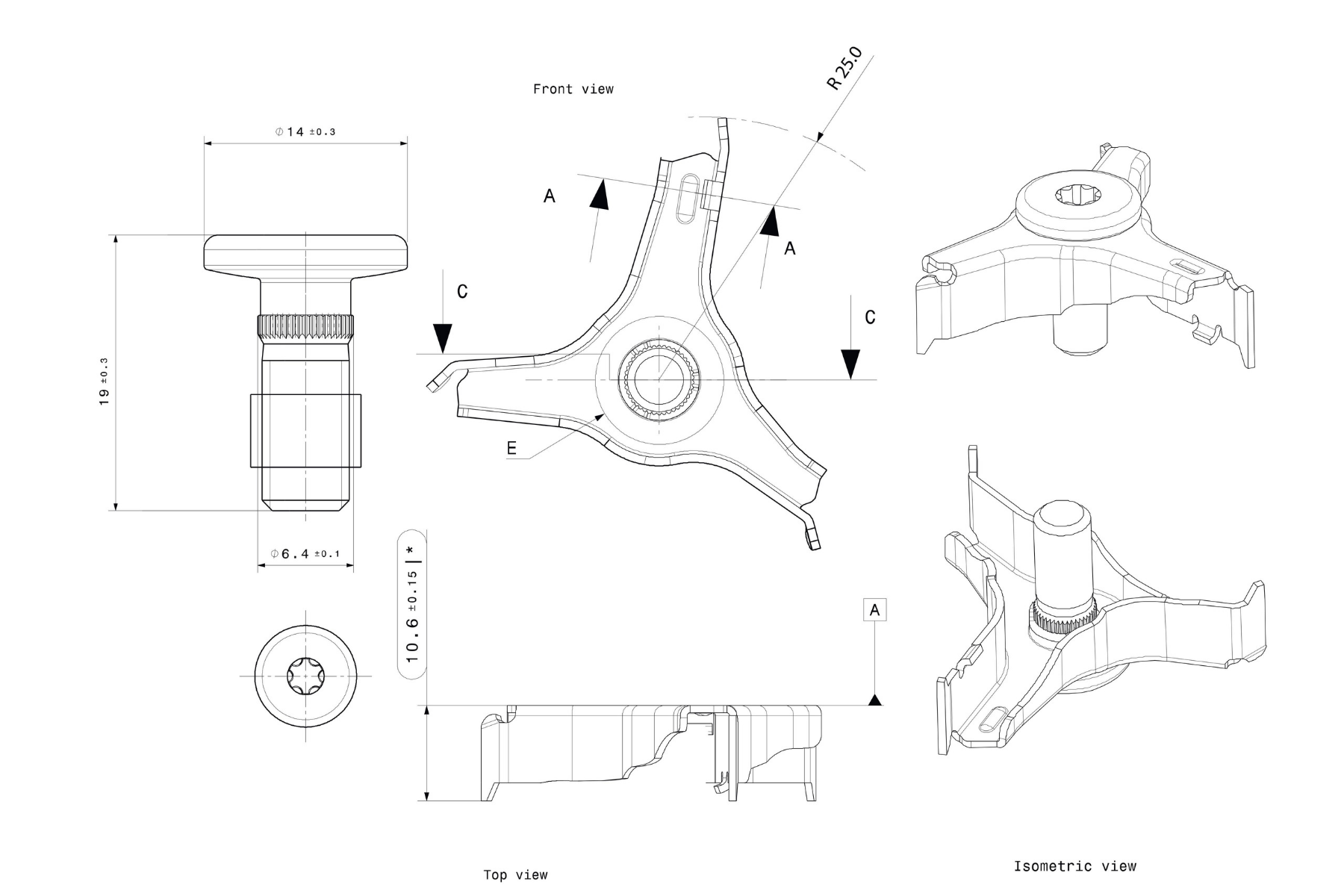

This project basically consisted of developing a solution that could attach the multimedia antennas of some Audi brand car models.

Multimedia antennas are a recent trend in the market, where in addition to the traditional radio antenna, mobile data access and navigation antennas are incorporated. Antennas are therefore more complex, bulkier and more sensitive. This solution not only had to ensure that this multimedia antenna was resiliently fixed to absorb vibrations, but also the watertightness of the passenger compartment.

This process involved the production of 600000 pieces per year and their respective assembly. It was a project with a very high degree of demand, as are all those related to the automotive sector.

Project development

The client sent the technical drawings of the part and, after the internal team carried out the evaluation, it was decided to use eight of ETMA’s integrated production processes, as follows:

- Prototype

- Tool and equipment manufacturing

- Stamping

- Cold forging and screws

- Heat treatment

- Surface treatment (zinc)

- Assembly

- Inspection and sorting

All these processes are carried out at ETMA’s facilities, unlike most companies that have to subcontract some of these services. ETMA offers internally all these processes providing several benefits for the client.

This project underwent a slight change throughout its development. Initially, it was planned to manufacture this piece with a high mechanical strength raw material, which placed some obstacles in the stamping process, in particular in the geometry conformation, tool wear and cycle time. We investigated the possibility of using raw material with lower initial mechanical strength, but that would later be hardened with heat treatment to ensure the performance sought by the client. This improved the manufacturing process, providing better manufacturability: the component met client requirements and it was possible to produce large quantities.

Advantages of the 10 integrated production processes

In this case study, it has been possible to identify several advantages of the 10 integrated production process model, as follows:

In this case study, it has been possible to identify several advantages of the 10 integrated production process model, as follows:

- greater control of the processes and their interaction and consequently greater flexibility;

- lower lead times, especially in multi-process production (for example, if surface and heat treatments had to be carried out externally, the lead time would increase exponentially);

- cost optimisation in terms of logistics and quality.

You can learn more about this system in the article “What is ETMA’s 10 Integrated Production Process System?”

Final considerations

The process reported here further demonstrates the way ETMA views its projects – from design to final product, and always in constant development. One of the advantages is to effectively participate in the development process of the part and promote an effective technical collaboration between the parties, so that it is functional for the client, feasible for ETMA and more cost-effective for both.

The process reported here further demonstrates the way ETMA views its projects – from design to final product, and always in constant development. One of the advantages is to effectively participate in the development process of the part and promote an effective technical collaboration between the parties, so that it is functional for the client, feasible for ETMA and more cost-effective for both.

Added to this, there are other important aspects as follows:

- comprehensive know-how in the metallurgy and metal-mechanic fields (nearly 80 years);

- extensive experience in the automotive sector, meeting all its requirements;

- qualified technical team always in search of quality and continuous improvement;

- ISO 9001/IATF 16949/ISO 14001 certification.

ETMA believes that the only way to achieve constant development is to be in close partnership with its clients, where everyone wins. If you would like to make an enquiry about a project, feel free to contact us.